Rain Test Equipment

RA-1 / RA-2 / RA-3 / RA-Z

The Rain Test Equipment that tests the water resistance and waterproofness of in-vehicle parts, electrical components, mobile devices, etc. International Protection Code (IP Code) is IPX1, IPX2, IPX3, IPX4, IPX4K, IPX5, IPX6, IPX6K, IPX7, IPX8, IPX9K, supported standards are SAE J575, IEC 60529, JIS C 0920, DIN 40050 (IP-Schutzarten), ISO 20653, JIS Supports a wide range of D 5020, JIS D 0203, and others.

Rain Test Equipment RA-1 / RA-2 / RA-3

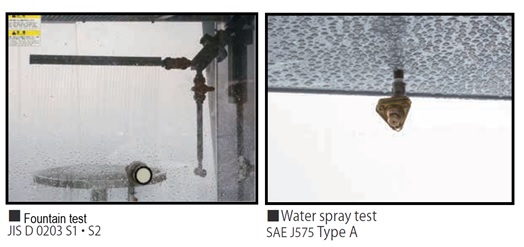

Test standard : SAE J575, JIS D 0203

Rain Test Equipment that tests the water resistance and waterproofness of in-vehicle parts such as automobile headlights and blinkers when they are exposed to wind, rain, or spray from the outside. You can easily switch the rotation speed, watering, and fountain of the sample rotary table.

- RA-1 complies and dedicated to SAE J575 Type A.

- RA-2 complies and dedicated to JIS D 0203.

- RA-3 complies with JIS D 0203 - spray test, fountain test, and SAE J575 Type A - water resistance test.

Available customization to control the chamber temperature and water tank temperature.

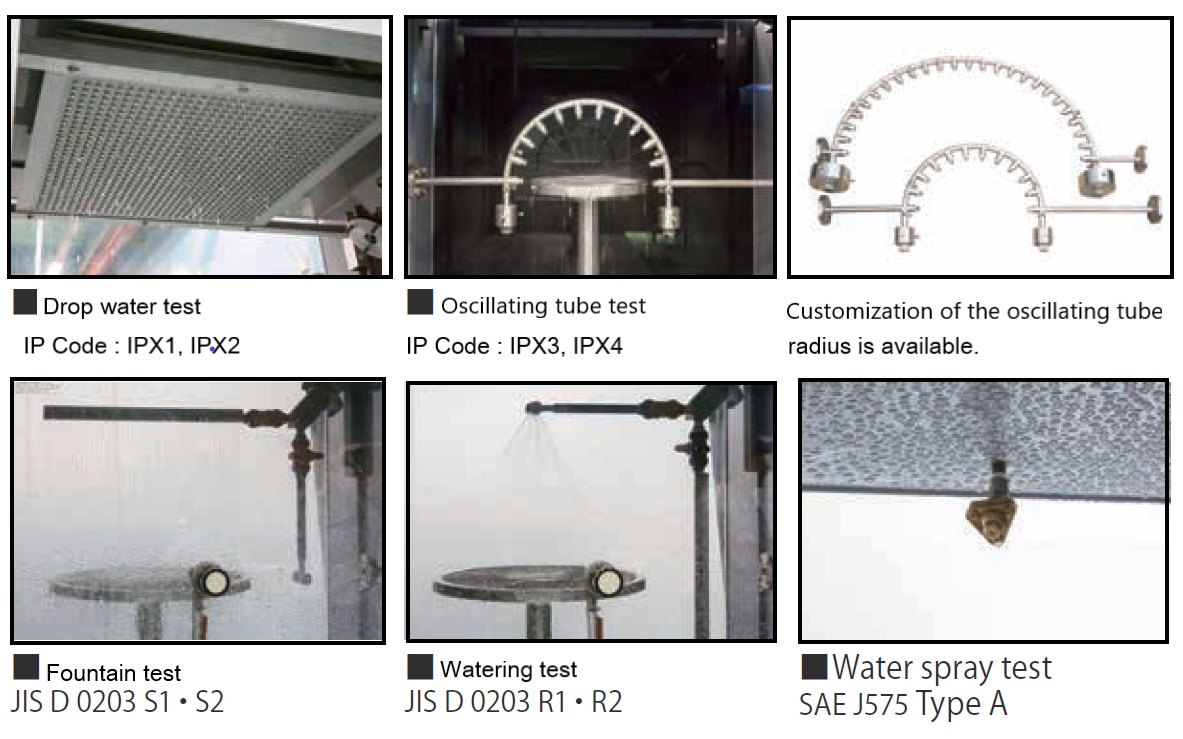

Rain Test Equipment RA-Z

Test standard : ISO 20653, IEC 60529, SAE J575, JIS D 5020, JIS C 0920

RA-Z tests the waterproof performance of in-vehicle electrical components and mobile products. Depending on the IP protection grade, various IEC, ISO, DIN, JIS tests such as oscillating tube test, drip-proof test, high-pressure injection test, etc. are supported, so please specify before ordering.

- You can easily switch between the rotation speed of the specimen rotary table, the water spray test, and the fountain test.

- Oscillating test operation is self-contained and the oscillating tube radius is customizable.

- The water temperature rise is suppressed by adjusting the water temperature by the overflow method.

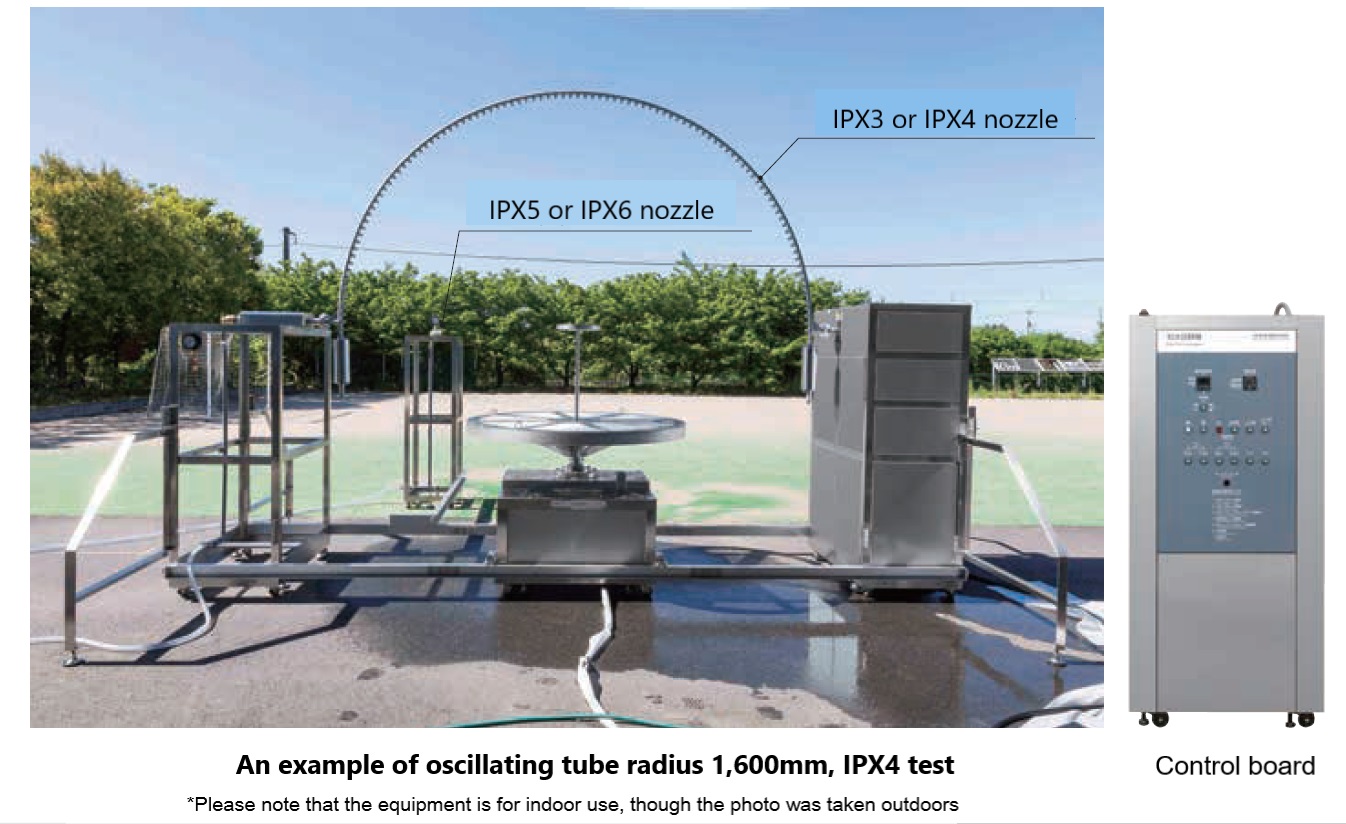

Rain Test Equipment RA-Z

Test standard : ISO 20653, IEC 60529, JIS D 5020, JIS C 0920

RA-Z performs a water resistance test to determine the protection class (IP Code) of a large test specimen. Testing of protection classes IPX3, IPX4, IPX5, IPX6 specified in JIS C 0920: 2003 is possible. The operation of the oscillating test is automatic. The maximum allowable radius of the oscillating tube is 1600 mm, and 8 tubes (radius 200/400/600/800/1000/1200/1400/1600 mm) are attached and replaceable according to the test specimen size.

Comparison of IP Code 2nd Characteristic Number

| IP Code | IEC 60529 (Degrees of protection provided by enclosures) |

DIN 40050 (IP-Schutzarten) | ISO 20653 (Road vehicles - Degrees of protection (IP-Code) Protection of electrical equipment foreign objects, water and access |

JIS D 5020 | ||||

|---|---|---|---|---|---|---|---|---|

| JIS C 0920 | ||||||||

| IPX1 | Drip box (Drop water test equipment) | Drip | Water drips vertically | Vertical falling water droplets | ||||

| 1mm/min | 1mm/min, Nozzle hole φ0.4mm | 1mm/min, Nozzle hole φ0.4mm | 1mm/min, Nozzle hole φ0.4mm | |||||

| IPX2 | Drip box (Drop water test equipment) | Drip | Water drips with enclosure inclined by 15° | Vertically falling water droplets on the outer shell inclined within 15° |

||||

| 3mm/min, Outer 15°, Slope | 3mm/min, Nozzle hole φ0.4mm, Outer 15°, Slope | 3mm/min, Nozzle hole φ0.4mm, Outer 15°, Slope | 3mm/min, Nozzle hole φ0.4mm, Outer 15°, Slope | |||||

| IPX3 | Spray nozzle | Oscillating tube | Spray nozzle | Oscillating tube | Shower tube | Swivel tube | Shower nozzle | Swivel tube |

| ± 60° with respect to the vertical direction, hole diameter φ0.5 mm |

± 60° with respect to the vertical direction, sprinkler hole φ0.4mm |

± 60° with respect to the vertical direction, hole diameter φ0.5 mm |

± 60° with respect to the vertical direction, sprinkler hole φ0.4mm |

± 60° with respect to the vertical direction, hole diameter φ0.5 mm |

± 60° with respect to the vertical direction, sprinkler hole φ0.4mm |

± 60° with respect to the vertical direction, hole diameter φ0.5 mm |

± 60° with respect to the vertical direction, sprinkler hole φ0.4mm |

|

| IPX4 | ± 180° with respect to the vertical direction, hole diameter φ0.5 mm |

± 180° with respect to the vertical direction, sprinkler hole φ0.4mm |

± 180° with respect to the vertical direction, hole diameter φ0.5 mm |

± 180° with respect to the vertical direction, sprinkler hole φ0.4mm |

± 180° with respect to the vertical direction, hole diameter φ0.5 mm |

± 180° with respect to the vertical direction, sprinkler hole φ0.4mm |

± 180° with respect to the vertical direction, hole diameter φ0.5 mm |

± 180° with respect to the vertical direction, sprinkler hole φ0.4mm |

| IPX4K | - | - | - | ± 180° with respect to the vertical direction, sprinkler hole φ0.8mm |

- | ± 180° with respect to the vertical direction, sprinkler hole φ0.8mm |

- | ± 180° with respect to the vertical direction, sprinkler hole φ0.8mm |

| IPX5 | Water jet nozzle | Water jet | High-velocity water | Water jet | ||||

| Nozzle hole φ6.3mm, distance 2.5~3m, 12.5L/min |

Nozzle hole φ6.3mm, distance 2.5~3m, 12.5L/min, 30kPa |

Nozzle hole φ6.3mm, distance 2.5~3m, 12.5L/min, 30kPa |

Nozzle hole φ6.3mm, distance 2.5~3m, 12.5L/min, 30kPa |

|||||

| IPX6 | Water jet nozzle | Strong water jet | Strong high-velocity water | Strong high-velocity water | ||||

| Nozzle hole φ12.5mm, distance 2.5~3m, 100L/min |

Nozzle hole φ12.5mm, distance 2.5~3m, 100L/min, 100kPa |

Nozzle hole φ12.5mm, distance 2.5~3m, 100L/min, 100kPa |

Nozzle hole φ12.5mm, distance 2.5~3m, 100L/min, 100kPa |

|||||

| IPX6K | ー | Strong water jet | Strong high-velocity water with increased pressure | Strong high-velocity water with increased pressure | ||||

| ー | Nozzle hole φ6.3mm, distance 2.5~3m, 75L/min, 1000kPa |

Nozzle hole φ6.3mm, distance 2.5~3m, 75L/min, 1000kPa |

Nozzle hole φ6.3mm, distance 2.5~3m, 75L/min, 1000kPa |

|||||

| IPX7 | Immersion tank | Temporary immersion in water | Temporary immersion in water | Temporary immersion in water | ||||

| 0.15m from the top of the outer shell to the water surface, 1m from the bottom to the water surface. |

0.15m from the top of the outer shell to the water surface, 1m from the bottom to the water surface. |

0.15m from the top of the outer shell to the water surface, 1m from the bottom to the water surface. |

0.15m from the top of the outer shell to the water surface, 1m from the bottom to the water surface. |

|||||

| IPX8 | Immersion tank | Continuous immersion in water | Continuous immersion in water | Continuous immersion in water | ||||

| Water level conditions are subject to consultation. | The water tank and water level are agreed upon by the parties. |

The water tank and water level are agreed upon by the parties. |

The water tank, water level, and procedure are agreed between the parties. |

|||||

| IPX9K | ー | Water during high-pressure / steam-jet cleaning | Water during high-pressure / steam-jet cleaning | Water during high-pressure / steam-jet cleaning | ||||

| ー | 14~16L/min, 8,000~10,000kPa | 14~16L/min, 8,000~10,000kPa | 14~16L/min, 8,000~10,000kPa | |||||