AISI 304 Stainless Steel Ball Bearings

AISI 304 stainless steel, widely used as corrosion- and heat-resistant steel and also as nonmagnetic steel, is most suitable in corrosive environments where AISI 440C stainless steel can not be used.

Features

- Higher corrosion resistance than AISI 440C stainless steel ball bearings

- Non-magnetic*1

- Difference in properties by the material used

| AISI 304 | AISI 440C | SAE 52100 | ||

|---|---|---|---|---|

| Specic Gravity | - | 7.93 | 7.8 | 7.8 |

| Tensile Strength | N/mm2 | 520 ~ 600 | 1900 ~ 2000 | 1680 |

| Elongation | % | 45 ~ 60 | - | - |

| Elastic Modulus | N/mm2 | 193000 | 203000 | 212000 |

| Hardness | HV | 170 | 700 | 740 |

| HRC | 3.0 | 60.1 | 61.8 | |

| Magnetism | - | Non magnetic*1 | Magnetic | Magnetic |

Note: The properties listed in the table are typical values.

*1 AISI 304 stainless steel may be magnetized depending on the processing method used.

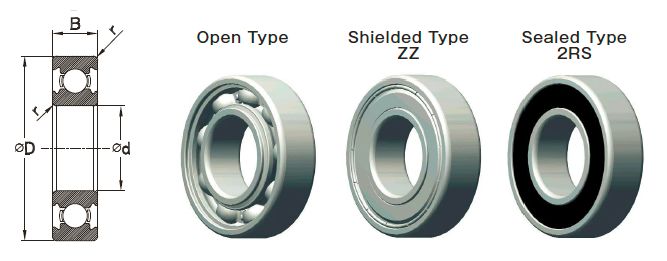

Specification

| Inner and Outer Rings | AISI 304 |

| Ball*1 | AISI 304 |

| Retainer | AISI 304 |

| Shield | AISI 304 |

| Seal*2 | Nitrile rubber (NBR) |

| Lubricant*3 | Heat resistant grease |

| Precision Grade | See ”Dimensions” |

Special bearings are also available in quick delivery with the specications below:

*1 Ceramic balls (Silicon nitride Si3N4)

*2 Fluorine rubber seal

*3 Heat- and chemical-resistant uorine grease and other special greases

Applications

LCD and semiconductor manufacturing equipment, metal plating equipment, other equipment used in environments where the bearings come into contact with acid or alkaline chemicals.

Precautions

AISI 304 stainless steel is not appropriate for use under heavy load or at medium to high rotation where AISI 440C stainless steel is usable, because it can not be hardened by heat treatment.

| Basic Part No. | d | D | B | r (min) |

Allowable Radial Load | Allowable Rotation | |||

| Boundary Dimension | Tole- rance |

Boundary Dimension | Tole- rance |

Boundary Dimension | Tole- rance |

||||

| mm | mm | mm | mm | N | rpm | ||||

| 6S 696B | 6 | +0.050 0 | 15 | 0-0.025 | 5 | 0-0.120 | 0.2 | 60 | 2300 |

| 6S 626B* | 6 | 19 | 6 | 0.3 | 130 | 2100 | |||

| 6S 698B* | 8 | 19 | 0-0.030 | 6 | 0.3 | 113 | 2100 | ||

| 6S 608B* | 8 | 22 | 7 | 0.3 | 165 | 2000 | |||

| 6S 628B | 8 | 24 | 8 | 0.3 | 168 | 2000 | |||

| 6S 6800B | 10 | 19 | 5 | 0.3 | 105 | 2200 | |||

| 6S 6900B | 10 | 22 | 6 | 0.3 | 135 | 2000 | |||

| 6S 6000B | 10 | 26 | 8 | 0.3 | 230 | 1800 | |||

| 6S 6200B | 10 | 30 | 9 | 0.6 | 255 | 1600 | |||

| 6S 6300B | 10 | 35 | 0-0.035 | 11 | 0.6 | 405 | 1400 | ||

| 6S 6801B | 12 | 21 | 0-0.030 | 5 | 0.3 | 95 | 1900 | ||

| 6S 6901B | 12 | 28 | 8 | 0.3 | 145 | 1800 | |||

| 6S 6001B | 12 | 28 | 8 | 0.3 | 255 | 1600 | |||

| 6S 6201B | 12 | 32 | 0-0.035 | 10 | 0.6 | 340 | 1500 | ||

| 6S 6802B | 15 | 24 | 0-0.030 | 5 | 0.3 | 105 | 1600 | ||

| 6S 6902B | 12 | 28 | 8 | 0.3 | 215 | 1500 | |||

| 6S 6002B | 15 | 32 | 0-0.035 | 9 | 0.3 | 280 | 1400 | ||

| 6S 6202B | 15 | 35 | 11 | 0.6 | 383 | 1300 | |||

| 6S 6903B | 17 | 30 | 0-0.030 | 7 | 0.3 | 230 | 1300 | ||

| 6S 6003B | 17 | 35 | 0-0.035 | 10 | 0.3 | 300 | 1200 | ||

| 6S 6203B | 17 | 40 | 12 | 0.6 | 478 | 1100 | |||

| 6S 6804B | 20 | 32 | 7 | 0.3 | 200 | 1200 | |||

| 6S 6904B | 12 | 28 | 8 | 0.3 | 320 | 1100 | |||

| 6S 6004B | 20 | 42 | 12 | 0.6 | 470 | 1000 | |||

| 6S 6204B | 20 | 47 | 14 | 1.0 | 643 | 930 | |||

| 6S 6805B | 25 | 37 | 7 | 0.3 | 215 | 1000 | |||

| 6S 6905B | 25 | 42 | 9 | 0.3 | 350 | 940 | |||

| 6S 6005B | 25 | 47 | 12 | 0.6 | 503 | 890 | |||

| 6S 6205B | 25 | 52 | 0-0.040 | 15 | 1.0 | 700 | 820 | ||

| 6S 6006B | 30 | 55 | 13 | 1.0 | 663 | 750 | |||

| 6S 6206B | 30 | 62 | 16 | 1.0 | 975 | 690 | |||

| 6S 6007B | 35 | 62 | 14 | 1.0 | 800 | 650 | |||

| 6S 6207B | 35 | 72 | 17 | 1.1 | 1288 | 590 | |||

| 6S 6008B | 40 | 68 | 15 | 1.0 | 838 | 590 | |||

| 6S 6208B | 40 | 80 | 18 | 1.1 | 1450 | 530 | |||

Note: Allowable radial load and rotations are provided for reference only.

* OPEN & ZZ types only.

Corrosion Resistance

| Chemicals | Condition | Temperature | AISI 304 Stainless Steel Ball Bearings |

|---|---|---|---|

| Chlorine | dry | ≦30ºC/86ºF | ○ |

| wet | × | ||

| Methylene Chloride | dry | ○ | |

| wet | ○ | ||

| Ammonium Chloride | 50% solution | △ | |

| Sodium Chloride | saturation | 100ºC/212ºF | ○ |

| Lithium Chloride | saturation | boiling point | ○ |

| Sulfuric Acid | solution up to 50% | 60ºC/140ºF | ○ |

| 95% to 100% solution | 149ºC/301ºF | ○ | |

| Sulfurous Acid Gas | dry | × | |

| wet | ○ | ||

| Nitric Acid | 0.5% to 40% solution | boiling point | ○ |

| 40% to 95% solution | 70ºC/158ºF | ○ | |

| Acetic Acid | solution up to 100% | boiling point | ○ |

| Citric Acid | solution up to 100% | ≦30ºC/86ºF | ○ |

| solution up to 15% | 65ºC/149ºF | △ | |

| Phosphoric Acid | ≦65% | ≦30ºC/86ºF | ○ |

| Ethanol (Ethyl Alcohol) | ≦30ºC/86ºF | ○ | |

| Cresol (Cresylic Acid) | dry | ○ | |

| Chlorine Gas | dry | ≦30ºC/86ºF | ○ |

| Seawater | △ | ||

| Caustic Soda | 10% solution | ○ | |

| Ammonium Sulfate | 50.4% solution | 120ºC/248ºF | ○ |

| Carbon Tetrachloride | dry | △ |

* ○not effected △slightly effected ×effected

Note: This comparison list is provided as general guidance for the users. The performance level of corrosion resistance varies, depending upon the conditions of each application.

※ The performance values on this catalog are not guaranteed and the specifications may change without prior notice for improved performance.