Multi-Axis Vibration Test Systems / Shakers

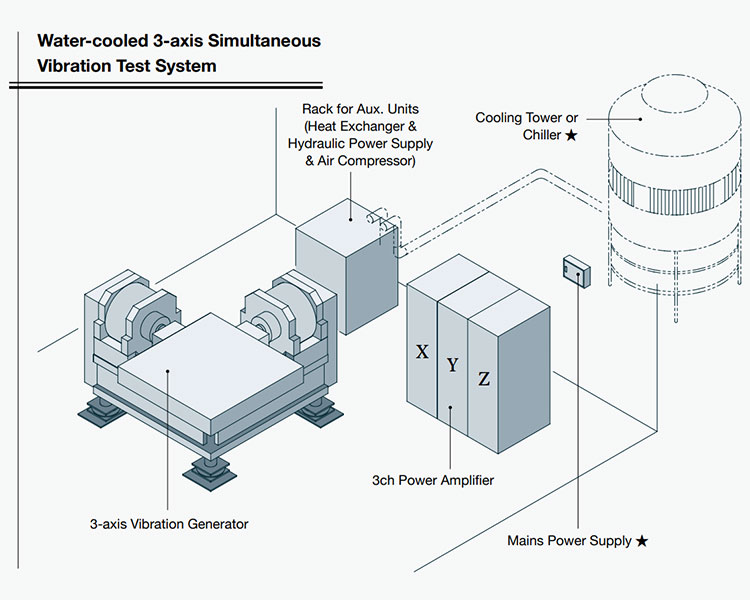

SHINKEN succeeded in commercializing the world’s first Electro-Dynamic Multi-Axis Vibration Test System. Since then, SHINKEN has been enjoying the world top-class installation record of Multi-Axis Vibration Test Systems with accumulated knowledge and long years experience as well as its uniquely-designed Hydrostatic Bearing System which minimizes cross-talks among axes and also makes the Multi-Axis Vibration Generators compact. In addition to simultaneous excitation, Multi-Axis Vibration Test Systems have been used for the sequential test of each axis thus contributing to time saving and labor elimination as no troublesome vertical & horizontal tables handling and also no specimen unloading & loading are needed. 2-axis and 3-axis Vibration Test Systems are available.

Advantages of SHINKEN

Reduction of Test Time and Labor

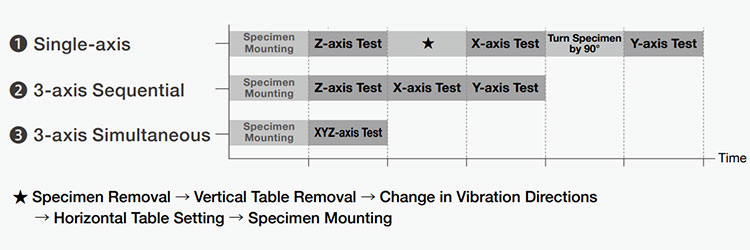

With the 3-axis Sequential Vibration Test Systems, vibration directions can be changed with one-touch switch operation or automatic direction change setting thus contributing to time saving and labor elimination as no troublesome vertical & horizontal tables handling and also no specimen unloading & loading are needed. With the 3-axis Simultaneous Vibration Test Systems, 3-axis simultaneous excitation can be carried out thus eliminating the test time drastically to less than 1/3.

Simulation of Real World-Like Vibrations

With the 3-axis Sequential Vibration Test Systems, vibration directions can be changed with one-touch switch operation or automatic direction change setting thus contributing to time saving and labor elimination as no troublesome vertical & horizontal tables handling and also no specimen unloading & loading are needed. With the 3-axis Simultaneous Vibration Test Systems, 3-axis simultaneous excitation can be carried out thus eliminating the test time drastically to less than 1/3.

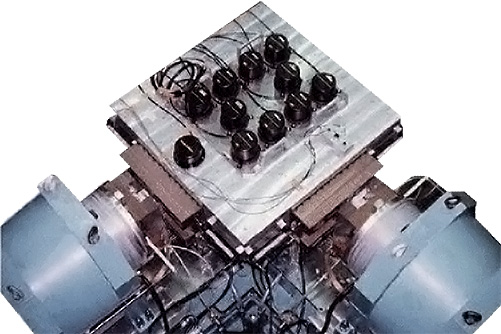

Minimizing "Cross-talks (Unnecessary Vibration)"

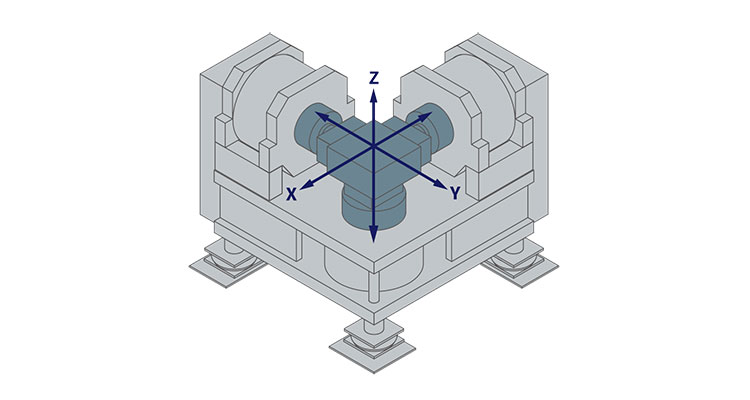

Long-experienced technology for the unique Multi-axis Hydrostatic Bearing Systems allows for restraint on "Cross-talks" among axes thus making it easy to well control in accordance with the set 3-axis vibration test conditions.

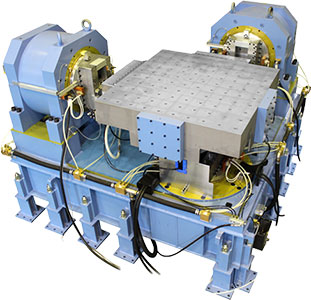

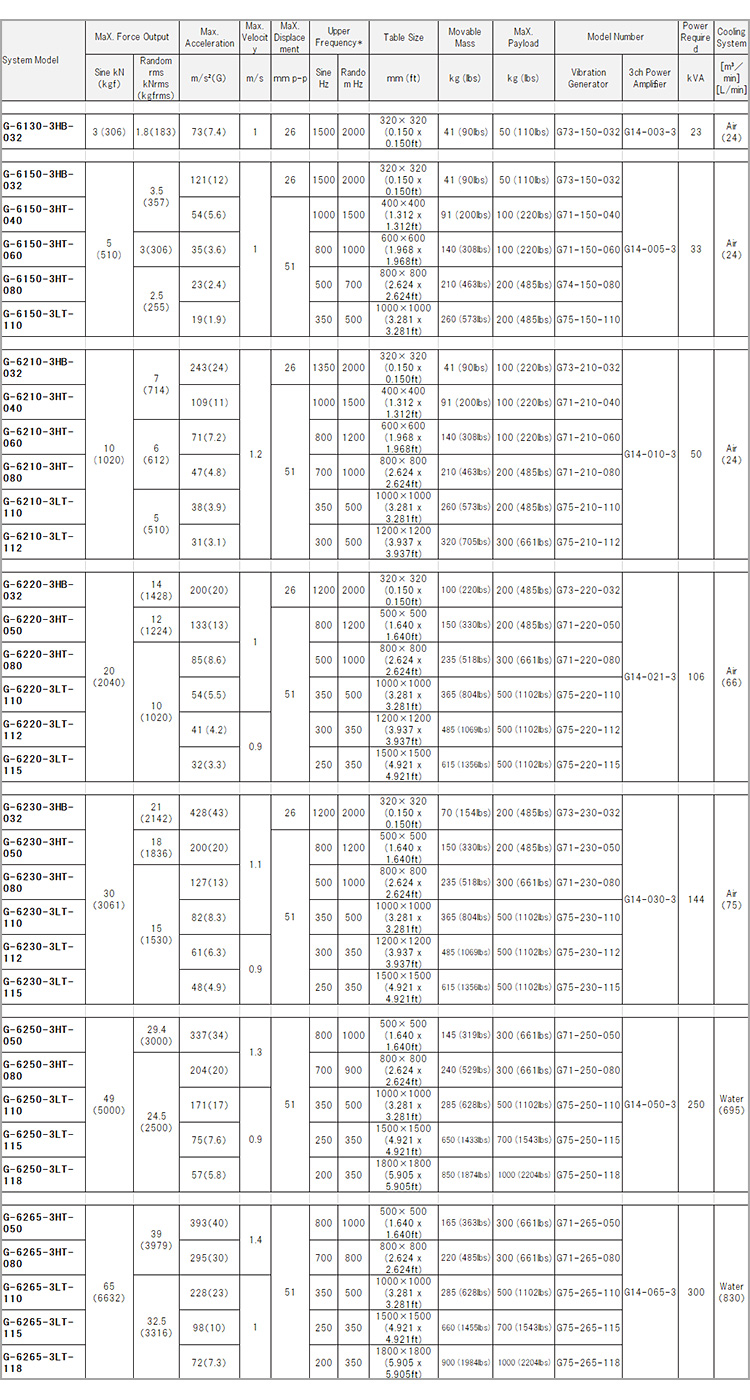

3-Axis Vibration Test Systems G-6 Series

Towards "More Realistic Vibration"

The G-6 Series Vibration Test Systems (VTSs) can create "More Realistic" vibration than any conventional Single-axis VTSs by exciting specimens in three directions; left & right(X), back & forth(Y) and up & down(Z), thus most suited to seismic simulation, transportation PSD simulation, actual vehicle running simulation etc.

Restraint on "Cross-talks" (Unnecessary Vibration)

Long-experienced technology for the unique Hydro-static Bearing systems allows for restraint on "Cross-talks" among the three axes, thus making it easy to control in accordance with the set 3-axis vibration test conditions.

3-axis Simultaneous VTSs & 3-axis Sequential VTSs Available

In addition to 3-axis Simultaneous VTSs, 3-axis Sequential VTSs, only capable of testing axis by axis with one-touch switch-over or optionally available automatic series tests (in order of Z→X→Y) are also available.

Model Number Example:G-6130-* HB-020

*3 =3-axis Simultaneous

1=3-axis Sequential

■Air-cooled ■Water-cooled ■Hydro-static Bearing ■Axis Changeover Switch ■Automatic Changeover (optional) ■Combined Environmental Test Systems also Available (optional)

1. The upper frequency for sine is a frequency up to which the max. force output can be achieved, while that for random is a frequency up to which a PSD random pattern having a -6dB/oct or steeper roll-off over the upper frequency for sine(or lower) can be controlled. The lower frequencies for control and for excitation are 2Hz and 0.5Hz, respectively unless especially requested. 2. All the Power Amplifiers are of an air cooling type. 3. The HT and LT type systems having a max. force output of 3kN(306kgf), 7kN(714kgf) or 20kN(2,040kgf) are also available. 4. With the employment of the 1-ch Power Amplifiers instead of the 3-ch Power Amplifier, the 3-axis (Automatic) Sequential Vibration Test Systems are also available, which can be upgraded into the Triaxial Simultaneous Vibration Test Systems in the future by adding 2-ch Power Amplifiers and necessary controllers. 5. Vibration Generators with other table sizes than shown above are also available upon request. 6. Power required is 3-phase 200/220/380/415V, 50/60Hz. 7. For better acceleration distribution on the table, the movable weight will be heavier by 10 to 30kg for addition of proper balance weights. 8. For the G-6230 (30kN), air-cooled systems are available upon request. 9. For the air-cooled systems, it is recommended that the hot air from the cooling blower be sent to outside. 10. A System having a bigger force output and/or larger displacement than shown above is also available upon request.

1. The upper frequency for sine is a frequency up to which the max. force output can be achieved, while that for random is a frequency up to which a PSD random pattern having a -6dB/oct or steeper roll-off over the upper frequency for sine(or lower) can be controlled. The lower frequencies for control and for excitation are 2Hz and 0.5Hz, respectively unless especially requested. 2. All the Power Amplifiers are of an air cooling type. 3. The HT and LT type systems having a max. force output of 3kN(306kgf), 7kN(714kgf) or 20kN(2,040kgf) are also available. 4. With the employment of the 1-ch Power Amplifiers instead of the 3-ch Power Amplifier, the 3-axis (Automatic) Sequential Vibration Test Systems are also available, which can be upgraded into the Triaxial Simultaneous Vibration Test Systems in the future by adding 2-ch Power Amplifiers and necessary controllers. 5. Vibration Generators with other table sizes than shown above are also available upon request. 6. Power required is 3-phase 200/220/380/415V, 50/60Hz. 7. For better acceleration distribution on the table, the movable weight will be heavier by 10 to 30kg for addition of proper balance weights. 8. For the G-6230 (30kN), air-cooled systems are available upon request. 9. For the air-cooled systems, it is recommended that the hot air from the cooling blower be sent to outside. 10. A System having a bigger force output and/or larger displacement than shown above is also available upon request.

3-Axis Simultaneous Seismic Simulator G-6245-3LT-130

Multi-axis Vibration Test Systems for Seismic Tests

With large displacement of 400mmp-p for horizontal and 200 mmp-p for vertical, this system has been used for calibration of all the seismometers installed all over Japan for quick information upon earthquake occurrence as well as simulation of various earthquakes.

Applications:

- Seismic Simulation

- Seismic Fragility Test for Structural Models

Long-Stroke 3-Axis Simultaneous Seismometer Calibrator

G-6230-3LT-115

Multi-axis Vibration Test Systems for Seismic Tests

With large displacement of 400mmp-p for horizontal and 200 mmp-p for vertical, this system has been used for calibration of all the seismometers installed all over Japan for quick information upon earthquake occurrence as well as simulation of various earthquakes.

Applications:

- Seismic Simulation

- Seismic Fragility Test for Structural Models

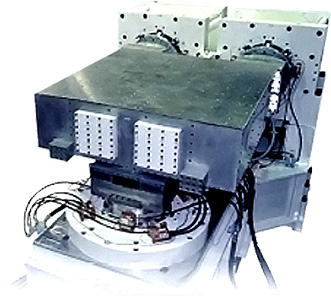

2-Axis Vibration Test Systems G-8 Series

Easier Change of Vibration Directions with One-touch Switch Operation

G-8 Series can eliminate time-consuming work for the specimen handling and changing vibration directions with one-touch switch operation, thus most suited to tests for large and heavy specimen.

Space-saving

G-8 Series' 2-axis Vibration Generators(VGs) have a common table for both horizontal and vertical excitation, thus making the space needed for the VGs smaller than the conventional single-axis VGs which require two tables; especially VGs with large tables.

Cost-saving

As it is said that vertical and the so-called "Major Horizontal" excitation can precipitate over 90% of the hidden flaws, 2-axis simultaneous excitation can be a lower cost solution.

2-axis Simultaneous VTSs & 2-axis Sequential VTSs Available

In addition to 2-axis Simultaneous VTSs, 2-axis Sequential VTSs, only capable of testing axis by axis with one-touch switch-over or optionally available automatic series tests (in order of Z→X) are also available.

Model Number Example:G-8130-*HB-020

*2 =2-axis Simultaneous /1=2-axis Sequential

■Air-cooled ■Water-cooled ■Hydro-static Bearing ■Axis Changeover Switch ■Automatic Changeover with Series Test Unit ■Combined Environmental Test Systems also Available

LB-type

Also available are LB-type 2-axis Vibration Test Systems with the table size changeable later, different from the HT- and LT-type. (Within the size of the VG's size)

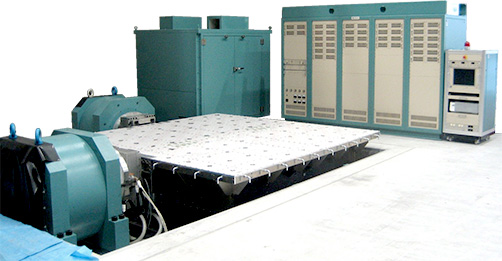

Multi-Axis Vibration Test Systems G-8340-1LT-120

Multi-axis Vibration Test Systems for Seismic Tests

With 2 pieces of Vibration Generators for both vertical and horizontal, this system can generate 400kN force for Sine and 1,000kN force for Shock, one of the largest in the world as the Electro-dynamic Multi-axis Vibration Test Systems.

- Max. Force Output: Sine 400kN, Shock 1,000kN

- Max. Acceleration: Sine 117m/s² (with 1.5 ton load) , Shock 300m/s² (-ditto-)

- Max. Displacement: 60mmp-p

- Frequency Range: 2 ~150Hz (-6dB or more roll-off over 100Hz)

- Table Size: 2 x 2m / 6.56 x 6.56ft (expandable to 4 x 4m / 13.12 x 13.12ft)

- Max. Payload: 2,000kg / 4409lbs (on 4 x 4m / 13.12 x 13.12ft table)

Applications:

- Seismic Simulation

- Seismic Fragility Test for Structural Models

Typical System Layout Plan

*Marked with ★: Scope of the Customer