AISI 440C Stainless Steel Ball Bearings

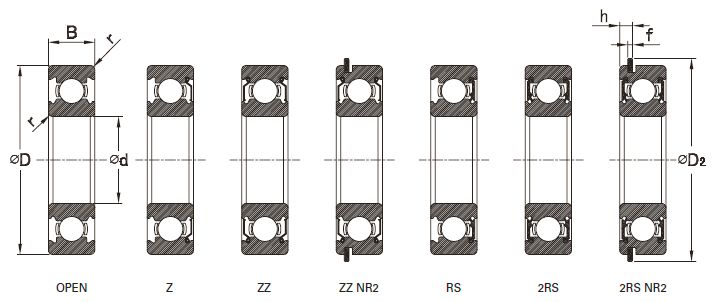

AISI 440C stainless steel ball bearings, resistant to rust, corrosion, and high temperature, are available from stock, in the series of 6000, 6200, 6300, 6800, and 6900.

Features

- Higher resistance to rust and corrosion than 52100 chrome bearing steel

●Recommended temperature rangeZZ type −40 ~ +150ºC/−40 ~ +302ºF 2RS type −30 ~ +110ºC/−22 ~ +230ºF Open type Subject to lubrication - Available with snap ring

Specification

| Inner and Outer Rings | AISI 440C |

| Ball*1 | AISI 440C |

| Retainer | AISI 304 |

| Shield | AISI 304 |

| Seal*2 | Nitrile rubber (NBR) |

| Snap Ring | AISI 304 |

| Lubricant*3 | Heat resistant grease |

| Precision Grade | JIS0 |

Special bearings are also available in quick delivery with the specications below:

*1 Ceramic balls (Silicon nitride Si3N4)

*2 Fluorine rubber seal

*3 Heat- and chemical-resistant uorine grease

and other special greases

4 C3 or C4 radial clearance

Applications

Food processing machinery, cleaning equipment, carrier device in watery environment, other equipment used in high temperature and humidity environments.

Precautions

1. AISI 440C stainless steel is magnetizable.

2. AISI 440C stainless steel may corrode depending on the environments and conditions.

3. Either AISI 304 or AISI 630 stainless steel ball bearings are also available where further corrosion resistance is required.

| BASIC PART NO. | d | D | B | r(min) | Basic Load Ratings | D2(max) | f(max) | h(max) | |||

| Cr | Cor | ||||||||||

| mm | mm | mm | mm | N | kg f | N | kg f | mm | mm | mm | |

| SS6800 | 10 | 19 | 5 | 0.3 | 2120 | 216 | 985 | 100 | ― | ― | ― |

| SS6900 | 10 | 22 | 6 | 0.3 | 2700 | 275 | 1270 | 130 | 24.8 | 0.70 | 1.75 |

| SS6000 | 10 | 26 | 8 | 0.3 | 4600 | 470 | 1970 | 201 | 28.8 | 0.84 | 2.19 |

| SS6200 | 10 | 30 | 9 | 0.6 | 5100 | 520 | 2390 | 243 | 34.7 | 1.12 | 3.18 |

| SS6300 | 10 | 35 | 11 | 0.6 | 8100 | 825 | 3450 | 350 | 39.7 | 1.12 | 3.18 |

| SS6801 | 12 | 21 | 5 | 0.3 | 1920 | 195 | 1040 | 106 | ― | ― | ― |

| SS6901 | 12 | 24 | 6 | 0.3 | 2890 | 295 | 1460 | 149 | 26.8 | 0.70 | 1.75 |

| SS6001 | 12 | 28 | 8 | 0.3 | 5100 | 520 | 2390 | 243 | 30.8 | 0.85 | 2.20 |

| SS6201 | 12 | 32 | 10 | 0.6 | 6800 | 695 | 3050 | 210 | 36.7 | 1.12 | 3.18 |

| SS6301 | 12 | 37 | 12 | 1.0 | 9700 | 990 | 4200 | 430 | 41.3 | 1.12 | 3.18 |

| SS6802 | 15 | 24 | 5 | 0.3 | 2080 | 212 | 1260 | 128 | ― | ― | ― |

| SS6902 | 15 | 28 | 7 | 0.3 | 4300 | 440 | 2250 | 230 | 30.8 | 0.85 | 2.15 |

| SS6002 | 15 | 32 | 9 | 0.3 | 5600 | 570 | 2840 | 290 | 36.7 | 1.12 | 3.18 |

| SS6202 | 15 | 35 | 11 | 0.6 | 7650 | 780 | 3750 | 380 | 39.7 | 1.12 | 3.18 |

| SS6302 | 15 | 42 | 13 | 1.0 | 11400 | 1170 | 5450 | 555 | 46.3 | 1.12 | 3.18 |

| SS6803 | 17 | 26 | 5 | 0.3 | 2630 | 268 | 1570 | 160 | ― | ― | ― |

| SS6903 | 17 | 30 | 7 | 0.3 | 4600 | 470 | 2550 | 260 | 32.8 | 0.85 | 2.15 |

| SS6003 | 17 | 35 | 10 | 0.3 | 6000 | 610 | 3250 | 330 | 39.7 | 1.12 | 3.18 |

| SS6203 | 17 | 40 | 12 | 0.6 | 9600 | 975 | 4800 | 490 | 44.6 | 1.12 | 3.18 |

| SS6303 | 17 | 47 | 14 | 1.0 | 13600 | 1390 | 6600 | 675 | 52.7 | 1.12 | 3.58 |

| SS6804 | 20 | 32 | 7 | 0.3 | 4000 | 410 | 2460 | 251 | ― | ― | ― |

| SS6904 | 20 | 37 | 9 | 0.3 | 6400 | 650 | 3700 | 375 | 39.8 | 0.85 | 2.55 |

| SS6004 | 20 | 42 | 12 | 0.6 | 9400 | 960 | 5050 | 515 | 46.3 | 1.12 | 3.18 |

| SS6204 | 20 | 47 | 14 | 1.0 | 12800 | 1310 | 6650 | 680 | 52.7 | 1.12 | 3.58 |

| SS6304 | 20 | 52 | 15 | 1.1 | 15900 | 1620 | 7850 | 800 | 57.9 | 1.12 | 3.58 |

| SS6805 | 25 | 37 | 7 | 0.3 | 4300 | 440 | 2940 | 300 | ― | ― | ― |

| SS6905 | 25 | 42 | 9 | 0.3 | 7000 | 715 | 4550 | 465 | 44.8 | 0.85 | 2.55 |

| SS6005 | 25 | 47 | 12 | 0.6 | 10100 | 1030 | 5850 | 600 | 52.7 | 1.12 | 3.18 |

| SS6205 | 25 | 52 | 15 | 1.0 | 14000 | 1430 | 7900 | 805 | 57.9 | 1.12 | 3.58 |

| SS6305 | 25 | 62 | 17 | 1.1 | 20600 | 2100 | 11200 | 1150 | 67.7 | 1.70 | 4.98 |

| SS6806 | 30 | 42 | 7 | 0.3 | 4550 | 465 | 3400 | 350 | ― | ― | ― |

| SS6906 | 30 | 47 | 9 | 0.3 | 7250 | 740 | 5000 | 510 | 49.8 | 0.85 | 2.55 |

| SS6006 | 30 | 55 | 13 | 1.0 | 13200 | 1350 | 8300 | 845 | 60.7 | 1.12 | 3.20 |

| SS6206 | 30 | 62 | 16 | 1.0 | 19500 | 1990 | 11300 | 1160 | 67.7 | 1.70 | 4.98 |

| SS6306 | 30 | 72 | 19 | 1.1 | 26700 | 2720 | 15000 | 1530 | 78.6 | 1.70 | 4.98 |

| SS6807 | 35 | 47 | 7 | 0.3 | 4750 | 485 | 3800 | 390 | ― | ― | ― |

| SS6907 | 35 | 55 | 10 | 0.6 | 10400 | 1060 | 7200 | 730 | ― | ― | ― |

| SS6007 | 35 | 62 | 14 | 1.0 | 16000 | 1630 | 10300 | 1050 | 67.7 | 1.70 | 3.78 |

| SS6207 | 35 | 72 | 17 | 1.1 | 25700 | 2620 | 15400 | 1570 | 78.6 | 1.70 | 4.98 |

| SS6307 | 35 | 80 | 21 | 1.5 | 33300 | 3400 | 19100 | 1950 | ― | ― | ― |

| SS6808 | 40 | 52 | 7 | 0.3 | 4950 | 505 | 4200 | 425 | ― | ― | ― |

| SS6908 | 40 | 62 | 12 | 0.6 | 13700 | 1400 | 9900 | 1010 | ― | ― | ― |

| SS6008 | 40 | 68 | 15 | 1.0 | 16800 | 1710 | 11600 | 1180 | 74.6 | 1.70 | 4.19 |

| SS6208 | 40 | 80 | 18 | 1.1 | 29100 | 2970 | 17900 | 1830 | ― | ― | ― |

| SS6308 | 40 | 90 | 23 | 1.5 | 40700 | 4150 | 24000 | 2440 | ― | ― | ― |

| SS6909 | 45 | 68 | 12 | 0.6 | 14100 | 1440 | 10900 | 1110 | ― | ― | ― |

| SS6009 | 45 | 75 | 16 | 1.0 | 21000 | 2140 | 15100 | 1540 | ― | ― | ― |

| SS6209 | 45 | 85 | 19 | 1.1 | 32700 | 3340 | 20500 | 2090 | ― | ― | ― |

| SS6309 | 45 | 100 | 25 | 1.5 | 53000 | 5400 | 32000 | 3260 | ― | ― | ― |

| SS6910 | 50 | 72 | 12 | 0.6 | 14500 | 1480 | 11700 | 1190 | ― | ― | ― |

| SS6010 | 50 | 80 | 16 | 1.0 | 21800 | 2220 | 16600 | 1690 | ― | ― | ― |

| SS6210 | 50 | 90 | 20 | 1.1 | 35100 | 3580 | 23200 | 2370 | ― | ― | ― |

| SS6310 | 50 | 110 | 27 | 2.0 | 62000 | 6320 | 38200 | 3900 | ― | ― | ― |

| SS6911 | 55 | 80 | 13 | 1.0 | 16600 | 1700 | 14100 | 1440 | ― | ― | ― |

| SS6011 | 55 | 90 | 18 | 1.1 | 28300 | 2880 | 21300 | 2170 | ― | ― | ― |

| SS6211 | 55 | 100 | 21 | 1.5 | 43400 | 4420 | 29400 | 2990 | ― | ― | ― |

| SS6311 | 55 | 120 | 29 | 2.0 | 71600 | 7300 | 44800 | 4570 | ― | ― | ― |

| SS6912 | 60 | 85 | 13 | 1.0 | 20200 | 2060 | 17300 | 1760 | ― | ― | ― |

| SS6012 | 60 | 95 | 18 | 1.1 | 29400 | 3000 | 23200 | 2360 | ― | ― | ― |

| SS6212 | 60 | 110 | 22 | 1.5 | 52400 | 5350 | 36100 | 3680 | ― | ― | ― |

| SS6312 | 60 | 130 | 31 | 2.1 | 81800 | 8350 | 52000 | 5300 | ― | ― | ― |

| SS6013 | 65 | 100 | 18 | 1.1 | 30500 | 3110 | 25200 | 2570 | ― | ― | ― |

| SS6213 | 65 | 120 | 23 | 1.5 | 57200 | 5830 | 40000 | 4080 | ― | ― | ― |

| SS6014 | 70 | 110 | 20 | 1.1 | 38000 | 3880 | 30900 | 3150 | ― | ― | ― |

| SS6214 | 70 | 125 | 24 | 1.5 | 62200 | 6340 | 44000 | 4490 | ― | ― | ― |

Corrosion Resistance

The following list shows the comparison of corrosion resistance performance between AISI 440C stainless steel and AISI 52100 normal bearing steel. Please consult with us regarding any other chemicals not listed below.

| Chemicals | Condition | Temperature | Materials | |

| 440C | 52100 | |||

| 4-chloridated carbon | dry / wet | normal | ○ | × |

| Acetic acid | ○ | × | ||

| Acetone | normal | ○ | - | |

| Air | normal | ○ | △ | |

| Carbonic acid gas | ○ | × | ||

| Chloric gas | dry | normal | △ | △ |

| Chloric gas | wet | 100ºC/212ºF | × | × |

| Hydrochloric acid | 75% solution | × | × | |

| Hydrogen peroxide | ○ | △ | ||

| Hydrogen sulfide gas | dry | ○ | △ | |

| Hydrogen sulfide gas | wet | ○ | △ | |

| Naphtha | normal | ○ | - | |

| Natural water | normal | ○ | × | |

| Nitric acid | thick | normal | ○ | × |

| Nitric acid | thick | boiling | × | × |

| Sea breeze | normal | ○ | × | |

| Seawater | normal | △ | × | |

| Seawater | 50% solution | normal / boiling | ○ | × |

| Sulfurous acid | thick | normal | ○ | △ |

| Sulfurous acid | thick | boiling | × | × |

| Sulfurous acid | 50% solution | normal / boiling | × | × |

| Sulfurous acid gas | dry | ○ | × | |

| Sulfurous acid gas | wet | ○ | × | |

| Water vapor | 100ºC/212ºF | ○ | × | |

Note : ○not effected △slightly effected ×effected -no data available

[Remarks]

This comparison list is provided as general guidance for the users. The performance level of corrosion resistance varies, depending upon the conditions of each application. Therefore, we recommend that the user conduct actual testing to see how 440C stainless steel works in the user-specific applications. We are not responsible for any claims taken place in the users’ applications without actual testing.