Combined Cyclic Corrosion Test Chambers (Instruments)

CCT-1LM / CCT-2LM / CCT-1L / CCT-2L / CCT-3L / CCT-1LX / DW-3 / DW-4

Combined Cyclic Corrosion Test Chambers (Instruments) that can perform cycle tests that combine 7 types of test items: salt spray, dry, wet, salt water immersion, outside air introduction, low temperature, and wet and high humidity, or these independent tests. Conform to typical tests such as ISO, IEC, SAE, ASTM, JIS, JASO, and is widely used all over the world.

Combined Cyclic Corrosion Test Chambers (Instruments)

CCT-1LM / CCT-2LM / CCT-1L / CCT-2L / CCT-3L

Test standard : ISO 9227, ISO 11130, ISO 14993, ISO 16151, ISO 16701, ISO 21207, ISO 14993, ISO 11997-1, ISO 11997-2, ISO 19453-4, ASTM B368, ASTM B117, ASTM G85, IEC 60068-2-11, IEC 60068-2-52, JIS Z 2371, JIS H 8502, JIS G0594, JIS K 5600-7-1, JIS K 5600-7-9, JIS K 5621, JIS K 5981, JIS H 8681-2, JASO M 609, JASO M 610, JIS D 0201, JIS D 0202, JIS C 60068-2-11, JIS C 60068-2-52, and more.

Combine 7 types of test items: salt spray, dry, wet, salt water immersion, outside air introduction, low temperature, and wet and high humidity, or these independent tests.

Uniform distribution of the salt mist.

International standard ISO 9227 prescribes the salt mist rate 1.5±0.5ml/h at 80cm², while the CCT series enable better accuracy 1.5±0.2ml/h at 80cm².

Air Barrier Board is equipped to suppress PH fluctuations (PAT.).

The Air Barrier Board which is prescribed in the ISO 9227 is equipped in the solution supply tank to block outside air and suppress PH fluctuations.

Short time temperature shifting by the steam heating method (PAT.).

By heating inside the test chamber with a steam pipe, the temperature inside the chamber rises quickly which makes the temperature distribution inside the chamber uniform.

Automatically cleans the temperature sensor during the test (PAT.).

The resistance temperature detector installed in the test tank is automatically cleaned during the test to prevent salt and dirt from adhering and fluctuating the measured value during the test.

The solution recovery mechanism suppresses pH fluctuations in the solution (PAT.).

During tests other than the spray test, the solution is collected from the solution reservoir at the bottom of the spray tower into the solution replenishment tank to suppress pH fluctuations.

Slope of the ceiling prevents water drops fall on the test specimen.

The lid and the chamber is sealed completely by water.

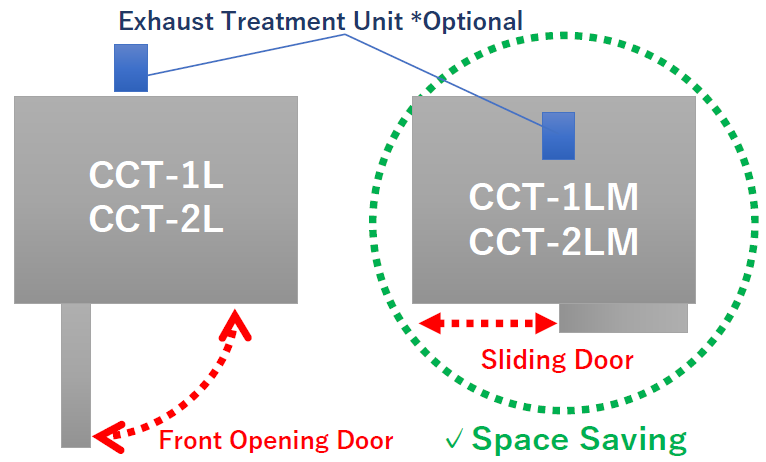

New Design of the Sliding Door & Built-In Exhaust Treatment Unit

*CCT-1LM / CCT-2LM

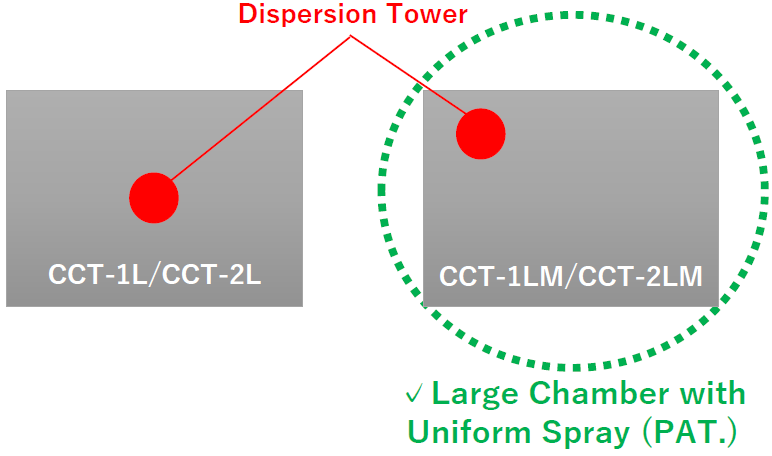

New Design of the Dispersion Tower which secures large space in the chamber (PAT.)

*CCT-1LM / CCT-2LM

Combined Cyclic Corrosion Test Chambers (Instruments) CCT-1LX

Light + Combined Cyclic Corrosion Test

CCT-1LX reproduces and promotes various harsh outdoor environments by arbitrarily combining conditions such as light irradiation, salt spray, drying, wetting, salt water immersion, and low temperature.

Combined Cyclic Corrosion Test Chambers (Instruments)

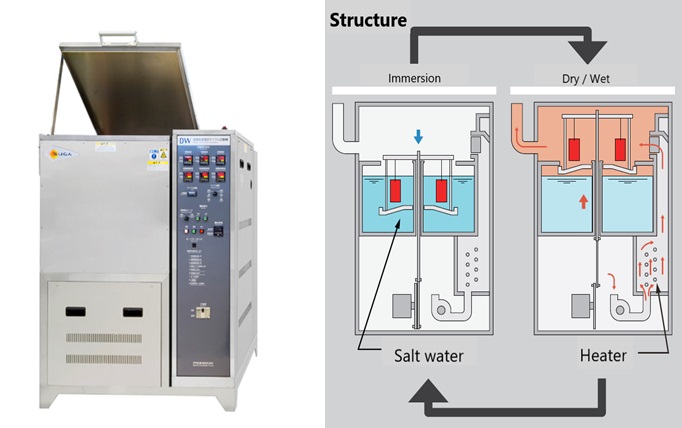

DW-3 / DW-4

Test standard : ISO 11130

Combines Immersion + Wet + Dry

DW that repeats the test conditions of salt water immersion, drying, and wetting. The automatic lifting device moves the specimen up and down between the upper part (drying and wet test) and the lower part (salt water immersion test) of the test chamber.

Standard Features

| Combined Cyclic Corrosion Test Chambers (Instruments) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | CCT-1LM | CCT-2LM | CCT-1L | CCT-2L | CCT-3L | DW-3 | DW-4 | ||

| Test item | Salt spray (neutral 5%) | 〇 | 〇 | 〇 | 〇 | 〇 | - | - | |

| CASS | - | - | - | - | - | - | - | ||

| Dry | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | ||

| Wet | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | ||

| Immersion* | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | ||

| Outside air introduction | 〇 | 〇 | 〇 | 〇 | 〇 | - | - | ||

| Low temp. | 〇 | 〇 | 〇 | 〇 | 〇 | - | - | ||

| Wet & High humidity | 〇 | 〇 | 〇 | 〇 | 〇 | - | - | ||

| Temperature & Humidity Range | Salt spray | Temp. | 35±1℃ (salt water neutral 5%), 50±1℃ | - | - | ||||

| Dry | Temp. | 20~70±1℃ | (RT+10)~80±1℃ | ||||||

| Humidity | 25±5%rh (at chamber temp.60℃) | - | - | ||||||

| Wet | Temp. | 50~70±1℃ | 40~50±1℃ | ||||||

| Humidity | 60~95±5%rh (at chamber temp.50℃) | 95%rh (when stable) | |||||||

| Immersion (salt water neutral 5%) | Temp. | (RT+10)~60±1℃ | (RT+10)~60±1℃ | ||||||

| Water level | approx.180mm | approx.220mm | approx.270mm | ||||||

| Outside air introduction | not controlled | - | - | ||||||

| Low temp. | Temp. | -20~20±1℃ *Available -40℃ as an option. | - | - | |||||

| Wet & High humidity | Temp. | 50±1℃ | - | - | |||||

| Humidity | 95%rh and above | - | - | ||||||

| Specimen capacity (150x70x1mm each) | 112 pcs | 238 pcs | 112 pcs | 228 pcs | 384 pcs | 40 pcs | 40 pcs | ||

| Specimen mounting angle (against vertical) | 15°or 20° | - | - | ||||||

| Chamber inner dimensions approx. (WDH) | 85x80x103cm (approx. 2.8x2.6x3.4 ft) | 150x80x103cm (approx. 4.9x2.6xx3.4ft) | 96x61x86cm (approx. 3.1x2.0x2.8ft) | 120x90x100cm (approx. 3.9x2.9x3.3ft) | 200x100x120cm (approx. 6.6x3.3x3.9ft) | 54x63x50cm (approx. 1.8x2.1x1.6ft) | 54x63x60cm (approx. 1.8x2.1x2.0ft) | ||

| Capacity w/o lid approx. | 700L (24.7 cu ft) | 1236L (43.6 cu ft) | 504L (17.8 cu ft) | 1080L (38.1 cu ft) | 2400L (84.8 cu ft) | 170L (6.0 cu ft) | 170L (6.0 cu ft) | ||

| Withstand load of specimen rack | 10 kgf (22.0lbf) | 20 kgf (44.1 lbf) | 10 kgf (22.0lbf) | 20 kgf (44.1 lbf) | 35 kgf (77.2 lbf) | 10 kgf (22.0lbf) | 18 kgf (40.0 lbf) | ||

| Electric capacity | 3 phase 200V, 63A (ELB: 75A) | 3 phase 200V, 73A (ELB: 100A) | 3 phase 200V, 61A (ELB: 75A) | 3 phase 200V, 81A (ELB: 100A) | 3 phase 200V, 144A (ELB: 160A) | 3 phase 200V, 27A (ELB: 30A) | 3 phase 200V, 27A (ELB: 30A) | ||

| Tap water requirements approx. | 0.6m³/day | 0.6m³/day | 0.5³/day | 0.6m³/day | 0.7m³/day | 1L/min | 1L/min | ||

| Pure water requirements approx. | 4.5L/h | 4.5L/h | 3.8L/h | 4.5L/h | 6.5L/h | 30L/h | 30L/h | ||

| Cooling water requirements approx. | 24L/min | 24L/min | 24L/min | 24L/min | 84L/min | - | - | ||

| External dimensions approx.(WDH) | 194x205x224cm (6.4x6.7x7.3ft) *With the touch panel folded | 264x205x224cm (8.7x6.7x7.3ft) *With the touch panel folded | 171x230x214cm (5.6x7.5x7.0ft) | 195x262x228cm (6.4x8.6x7.5ft) | 358x257x277cm (11.7x8.4x9.1ft) | 112x98x121cm (3.7x3.2x4.0ft) | 112x98x145cm (3.7x3.2x4.8ft) | ||

| Operating weight approx. | 1300kgs (2866lbs) | 1550kgs (3417lbs) | 1200kgs (2646lbs) | 1950kgs (4299lbs) | 2500kgs (5512lbs) | 320kgs (705lbs) | 370kgs (816lbs) | ||

*Available -40℃ as an option.

**Chamber inner dimensions of CCT-2LM : W150xD80xH103cm (W59.1xD31.5xH40.6in)

**The specifications above are subject to change without notice.

Exhaust Treatment Unit (Optional)

EF-1R / EF-2R

Completely remove the salt solution in the exhaust

Exhaust salt mist during the test is removed by passing it through the water spray. Treated water is circulated and reused by a pump, reducing consumption.

EF-1R for CCT-1, CCT-1L, CCT-2, CCT-2L

EF-2R for CCT-3, CCT-3L

Other Options for Corrosion Test Chambers (Instruments)

Exhaust Treatment Unit

Automatic Solution Supplying Unit

Automatic Pure Water Supply System to Air Saturators

Water Recycling Unit

and more.