Gas Corrosion Test Instruments

GT-100 / GS-UVZ / GS-UVS / GS-P / GS-DIN

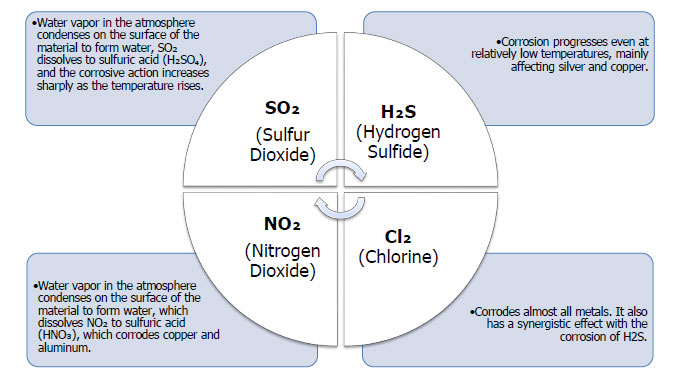

The Gas Corrosion Test Instruments are used to evaluate corrosion resistance of electronic components, components with metallic or organic coatings against a single gas or mixed gases of SO₂ (Sulfur Dioxide), H₂S(Hydrogen Sulfide), NO₂(Nitrogen Dioxide), and Cl₂(Chlorine). Test standards such as IEC 60068-2-42, IEC 60068-2-43, IEC 60068-2-60, JEITA CP3901A, DIN 50018 (ISO 3231 / ISO 6988) Kesternich test, ASTM G85, ISO 10062, ISO 21207, ISO 19453-4, JIS H8502, JIS C 60068-2-42, JIS C 60068-2-43, JIS C 60068-2-60, are applicable.

Since the gas easily dissolves in the liquid and the concentration tends to decrease due to a chemical reaction with the test specimen, it becomes a factor that greatly affects the reproducibility of the test results. Therefore, our gas corrosion tester adopts a double chamber method to prevent dew condensation on the inner wall of the test chamber, and completely shuts off the inner wall of the chamber (Patented). In addition, we have adopted an optical measurement method for gas concentration measurement, and have established the structure and control system to completely reproduce the test.

Gas Corrosion Test Instrument GT-100

GT-100 is capable of performing a gas corrosion test specified in the standard of ISO, IEC, JIS and so on to evaluate corrosion resistance of the test specimen. Referring to IEC 60068-2-60 (Environmental Testing - Part 2: Test Ke : Flowing mixed gas corrosion test), a Chlorine has a highly reactive, and once a test containing the Chlorine has been conducted, it will remain not only in the chamber but also in the pipings as well. Since the residual Chlorine shows strong interaction especially through reaction with Hydrogen Sulfide, there is a possibility that affects on the test results. Moreover, it is extremely difficult to completely eliminate the Chlorine from the sections that have been exposed to Chlorine.

Chamber Exchanging System(PAT.)

Exchangeable test chamber for both conducting tests using and without using Cl₂(Chlorine). The test chamber and parts are removable to completely eliminate the Chlorine.

Dew Free System (PAT.)

By the method of taking air that has been temperature-controlled and humidity-controlled in advance into the test chamber, dew condensation that affects the gas concentration is prevented, and at the same time, the stability of the gas concentration and temperature and humidity is much improved.

Easy to place and remove the test specimen by the front door system.

Comparing to the previous model which had conventional upper lid system, the front door system make it much easier to place and remove the test specimen and improved workability.

Gas Corrosion Test Instrument GS-UVZ

Custom chambers for customer-specific specifications

Gas Corrosion Test Instrument GS-DIN

Complies with DIN 50018 (ISO 3231 / ISO 6988), Kesternich test method.

Gas Corrosion Test Instrument GS-P

Complies with Digital color print image preservability test method (JEITA CP3901A)

Gas Corrosion Test Instrument GS-UVS

GS-UVS operates a programmed temperature-humidity test using an automatically controlled gas mixture of SO2, H2O and NO₂, without any leakage from the walls in the chamber.

Temperature and humidity cyclic test, automatic gas concentration control model (PAT.)

Since no dew condensation occurs on the inner wall of the test tank even when the temperature and humidity rise and fall, it enables temperature and humidity cycle tests with stable gas concentration.

Standard Features

| Name | Gas Corrosion Test Instrument | |||

|---|---|---|---|---|

| Model | GT-100 | GS-UVS | ||

| Gas *Select before placing an order |

SO2 | Sulfur Dioxide | 〇 | 〇 |

| H2S | Hydrogen Sulfide | 〇 | 〇 | |

| NO2 | Nitrogen Dioxide | 〇 | 〇 | |

| Cl2 | Chlorine | 〇 | - | |

| Gas Concentration Range *Adjustment manually |

SO2 | Sulfur Dioxide | 0.1 ~ 200ppm | 0.01 ~ 200ppm |

| H2S | Hydrogen Sulfide | 0.01 ~ 200ppm | 0.01 ~ 200ppm | |

| NO2 | Nitrogen Dioxide | 0.1 ~ 20ppm | 0.2 ~ 20ppm | |

| Cl₂ | Chlorine | 0.01 ~ 20ppm | - | |

| Gas Concentration Adjustment | Manual adjustment | Manual adjustment *Option: Automatic adjustment |

||

| Temperature and Humidity Range |

Temperature | 20~65±1℃ | 23~50±1℃ | |

| Humidity | 65~95±3%rh (at chamber temperature 20℃), 30~95±3%rh (at chamber temperature 65℃) |

75±3%rh (at chamber temperature 25℃) |

||

| 70~75±3%rh (at chamber temperature 30℃) |

||||

| 60~95±3%rh (at chamber temperature 40℃, 50℃) |

||||

| Test Specimen | Quantity (per 150x70x1mm) | 20 | 20 | |

| Angle to mount against vertical | 0°or 15° | 0°or 15° | ||

| Inner Chamber Dimensions | approx. W50xD50xH40cm (W19.7xD19.7xH15.7in) |

approx. W50xD50xH60cm (W19.7xD19.7xH23.6in) |

||

| Electrical Requirements | 50/60Hz | 3 Phase 200V approx. 19A | 3 Phase 200V approx. 22A | |

| Earth Leakage Breaker (ELB) | ELB: 30A | ELB: 30A | ||

| Water Requirements | Pure water for Humidifier | approx. 0.8L/h (0.21GPH) | approx. 0.8L/h (0.21GPH) | |

| External Dimensions | Including pipings | approx. W132xD169xH198cm (W52.0xD66.5xH78.0in) |

approx. W136xD142xH216cm (W53.5xD55.9xH85.0in) |

|

| Operating Weight | appox.570kgs (1257lbs) | appox.600kgs (1323lbs) | ||