SF series - AISI440C Flanged Bearing Units

SMT SF series are high-precision flanged bearing units made with single low deep groove stainless bearing and stainless bearing housing, that can be fixed directly to machine and equipment easily with four bolts. SMT bearing units can contribute significantly to cost reduction by simplified facility design and improved work efficiency.

Features

Corrosion Resistance

Both bearing and housing made of AISI440C stainless steel are superior for corrosion resistance and clean environment, therefore suitable for use in food machinery, equipment in clean room, chemical processing machine, cleaning equipment, and equipment that should look beautiful.

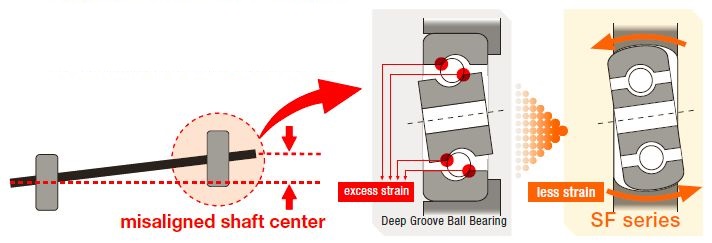

Aligning Function(SSA and SSXCA types)

Aligning function can reduce the stress on the bearing by the error of shaft center and by the flexure of the shaft.

Fit

The adequate fit is maintained between the bearing and the housing because no difference occurs in the amount of expansion and contraction by using AISI440C stainless steel for both components.

Mounting

Best used for the applications that require precise positioning by the precision finishing. As for SSCXA and SSXC types, shaft can be easily fastened with set screws.

Specification

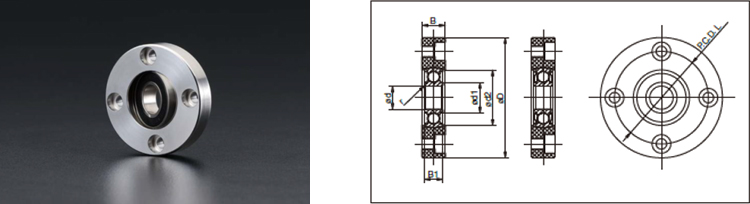

SSA type with aligning function

OPEN, ZZ and 2RS

Example: SS A6000 2RS SFA

| Specifications | |||

| Bearing | SSA type Spherical O.D |

Rings | AISI440C |

| Balls | AISI440C | ||

| Cage | AISI304 | ||

| Shields | AISI304 | ||

| Seals | NBR | ||

| Housing | AISI440C | ||

| Lubrication | Heat-resistant grease | ||

Special specifications also avaliable upon request.

| Bearing number | d | B1 | D | B | L | d1 | d2 | r | Bolt size | Cr | Cor |

| mm | mm | mm | mm | mm | mm | mm | mm | - | N | N | |

| SS A6000 SFA | 10 | 8 | 52 | 10 | 40 | 13.31 | 24.39 | 0.3 | M4 | 4600 | 1970 |

| SS A6200 SFA | 10 | 9 | 55 | 10 | 43 | 16.01 | 28.61 | 0.6 | M4 | 5100 | 2390 |

| SS A6001 SFA | 12 | 8 | 55 | 10 | 43 | 16.01 | 26.51 | 0.3 | M4 | 5100 | 2390 |

| SS A6201 SFA | 12 | 10 | 58 | 12 | 45.5 | 16.75 | 30.05 | 0.6 | M5 | 6800 | 3050 |

| SS A6002 SFA | 15 | 9 | 58 | 12 | 45.5 | 19.01 | 30.05 | 0.3 | M5 | 5600 | 2840 |

| SS A6202 SFA | 15 | 11 | 68 | 12.5 | 52 | 20.25 | 33.06 | 0.6 | M5 | 7650 | 3750 |

| SS A6003 SFA | 17 | 10 | 68 | 12.5 | 52 | 21.51 | 33.06 | 0.3 | M5 | 6000 | 3250 |

| SS A6203 SFA | 17 | 12 | 72 | 14 | 57 | 22.25 | 37.93 | 0.6 | M6 | 9600 | 4800 |

| SS A6004 SFA | 20 | 12 | 72 | 14 | 57 | 25.11 | 40.03 | 0.6 | M6 | 9400 | 5050 |

| SS A6204 SFA | 20 | 14 | 80 | 15.5 | 64 | 26.99 | 44.80 | 1.0 | M6 | 12800 | 6650 |

| SS A6005 SFA | 25 | 12 | 80 | 15.5 | 64 | 30.12 | 44.80 | 0.6 | M6 | 10100 | 5850 |

| SS A6205 SFA | 25 | 15 | 95 | 17 | 76 | 32.84 | 49.69 | 1.0 | M8 | 14000 | 7900 |

| SS A6006 SFA | 30 | 13 | 95 | 17 | 76 | 35.91 | 52.71 | 1.0 | M8 | 13200 | 8300 |

| SS A6206 SFA | 30 | 16 | 105 | 18.5 | 86 | 38.54 | 59.67 | 1.0 | M8 | 19500 | 11300 |

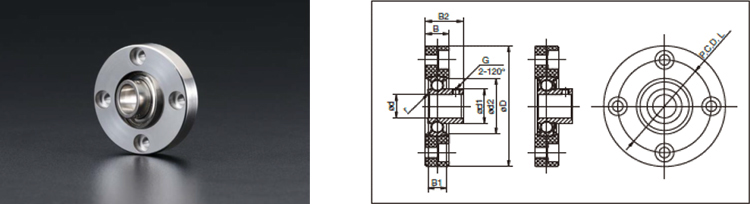

SSXCA type with aligning function and set screw

OPEN and ZZ

Example: SS XCA6000 ZZ SFA

| Specifications | |||

| Bearing | SSXCA type Spherical O.D. with set screw |

Rings | AISI440C |

| Balls | AISI440C | ||

| Cage | AISI304 | ||

| Shields | AISI304 | ||

| Set screws | AISI304 equivalent | ||

| Housing | AISI440C | ||

| Lubrication | Heat-resistant grease | ||

Special specifications also avaliable upon request.

| Bearing number | d | B1 | B2 | G | D | B | L | d1 | d2 | r | Bolt size | Cr | Cor | |

| mm | Tolerance | mm | mm | - | mm | mm | mm | mm | mm | mm | - | N | N | |

| SS XCA6000 SFA | 10 | +0.015 0 | 8 | 16 | M3 | 52 | 10 | 40 | 14.86 | 24.39 | 0.3 | M4 | 4600 | 1970 |

| SS XCA6200 SFA | 10 | 9 | 17.5 | M4 | 55 | 10 | 43 | 17.45 | 28.61 | 0.6 | M4 | 5100 | 2390 | |

| SS XCA6001 SFA | 12 | 8 | 16 | M3 | 55 | 10 | 43 | 17.45 | 26.51 | 0.3 | M4 | 5100 | 2390 | |

| SS XCA6201 SFA | 12 | 10 | 20 | M4 | 58 | 12 | 45.5 | 18.19 | 30.05 | 0.6 | M5 | 6800 | 3050 | |

| SS XCA6002 SFA | 15 | 9 | 18 | M3 | 58 | 12 | 45.5 | 20.45 | 30.05 | 0.3 | M5 | 5600 | 2840 | |

| SS XCA6202 SFA | 15 | 11 | 20.75 | M4 | 68 | 12.5 | 52 | 21.69 | 33.06 | 0.6 | M5 | 7650 | 3750 | |

| SS XCA6003 SFA | 17 | 10 | 18.75 | M4 | 68 | 12.5 | 52 | 22.95 | 33.06 | 0.3 | M5 | 6000 | 3250 | |

| SS XCA6203 SFA | 17 | 12 | 22 | M5 | 72 | 14 | 57 | 24.68 | 37.93 | 0.6 | M6 | 9600 | 4800 | |

| SS XCA6004 SFA | 20 | +0.018 0 |

12 | 22 | M5 | 72 | 14 | 57 | 27.44 | 40.03 | 0.6 | M6 | 9400 | 5050 |

| SS XCA6204 SFA | 20 | 14 | 23.75 | M5 | 80 | 15.5 | 64 | 29.22 | 44.80 | 1.0 | M6 | 12800 | 6650 | |

| SS XCA6005 SFA | 25 | 12 | 23.75 | M5 | 80 | 15.5 | 64 | 32.04 | 44.80 | 0.6 | M6 | 10100 | 5850 | |

| SS XCA6205 SFA | 25 | 15 | 27 | M5 | 95 | 17 | 76 | 33.92 | 49.69 | 1.0 | M8 | 14000 | 7900 | |

| SS XCA6006 SFA | 30 | 13 | 26.5 | M5 | 95 | 17 | 76 | 37.93 | 52.71 | 1.0 | M8 | 13200 | 8300 | |

| SS XCA6206 SFA | 30 | 16 | 29.75 | M6 | 105 | 18.5 | 86 | 40.60 | 59.67 | 1.0 | M8 | 19500 | 11300 | |

Bearing can be dismounted from housing. Location of set screw can be reversed.

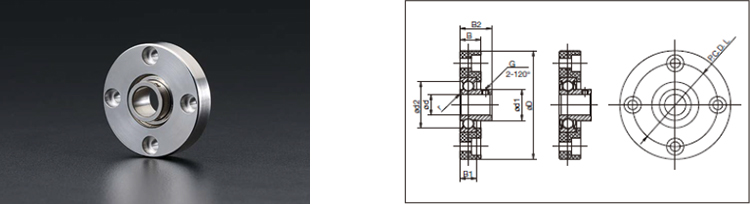

SSXC type with set screw

OPEN and ZZ

Example: SS XC000 ZZ SF

| Specifications | |||

| Bearing | SSXC type Spherical O.D. with set screw |

Rings | AISI440C |

| Balls | AISI440C | ||

| Cage | AISI304 | ||

| Shields | AISI304 | ||

| Set screws | AISI304 equivalent | ||

| Housing | AISI440C | ||

| Lubrication | Heat-resistant grease | ||

Special specifications also avaliable upon request.

| Bearing number | d | B1 | B2 | G | D | B | L | d1 | d2 | r | Bolt size | Cr | Cor | |

| mm | Tolerance | mm | mm | - | mm | mm | mm | mm | mm | mm | - | N | N | |

| SS XC000 SF | 10 | +0.015 0 | 8 | 15 | M3 | 52 | 10 | 40 | 14.86 | 22.00 | 0.3 | M4 | 4600 | 1970 |

| SS XC200 SF | 10 | 9 | 17 | M4 | 55 | 10 | 43 | 17.45 | 24.00 | 0.6 | M4 | 5100 | 2390 | |

| SS XC001 SF | 12 | 8 | 15 | M3 | 55 | 10 | 43 | 17.45 | 24.00 | 0.3 | M4 | 5100 | 2390 | |

| SS XC201 SF | 12 | 10 | 19 | M4 | 58 | 12 | 45.5 | 18.19 | 27.00 | 0.6 | M5 | 6800 | 3050 | |

| SS XC002 SF | 15 | 9 | 16.5 | M3 | 58 | 12 | 45.5 | 20.45 | 27.00 | 0.3 | M5 | 5600 | 2840 | |

| SS XC202 SF | 15 | 11 | 20 | M4 | 68 | 12.5 | 52 | 21.69 | 30.00 | 0.6 | M5 | 7650 | 3750 | |

| SS XC003 SF | 17 | 10 | 17.5 | M4 | 68 | 12.5 | 52 | 22.95 | 30.00 | 0.3 | M5 | 6000 | 3250 | |

| SS XC203 SF | 17 | 12 | 21 | M5 | 72 | 14 | 57 | 24.68 | 35.00 | 0.6 | M6 | 9600 | 4800 | |

| SS XC004 SF | 20 | +0.018 0 | 12 | 21 | M5 | 72 | 14 | 57 | 27.44 | 35.00 | 0.6 | M6 | 9400 | 5050 |

| SS XC204 SF | 20 | 14 | 23 | M5 | 80 | 15.5 | 64 | 29.22 | 41.00 | 1.0 | M6 | 12800 | 6650 | |

| SS XC005 SF | 25 | 12 | 22 | M5 | 80 | 15.5 | 64 | 32.04 | 41.00 | 0.6 | M6 | 10100 | 5850 | |

| SS XC205 SF | 25 | 15 | 26 | M5 | 95 | 17 | 76 | 33.92 | 46.00 | 1.0 | M8 | 14000 | 7900 | |

| SS XC006 SF | 30 | 13 | 24.5 | M5 | 95 | 17 | 76 | 37.93 | 46.00 | 1.0 | M8 | 13200 | 8300 | |

| SS XC206 SF | 30 | 16 | 28.5 | M6 | 105 | 18.5 | 86 | 40.60 | 54.00 | 1.0 | M8 | 19500 | 11300 | |

Bearing can be dismounted from housing. Location of set screw can be reversed.

Precautions

Please refer to the charts for the tightening torque. Too much torque may damage the bearing. Adhesive bond is not recommended that may increase the tightening force and result in the breakage of bearing.

Set screw recommended torque

| Sizes | Torque N.m |

| M3 | 0.7 |

| M4 | 1.8 |

| M5 | 3.0 |

| M6 | 4.0 |

Mounting bolt recommended torque

| Sizes | Torque N.m |

| M4 | 1.8 |

| M5 | 3.0 |

| M6 | 4.0 |

| M8 | 8.5 |

Performance data and values are for reference only.

They are not guaranteed and are subject to change without notice.