CASS Test Chambers (Instruments)

CAP-100 / CAP-110 / CAP-120 / CAP-160 / CAP-200 / CAP-90VR

The CASS test is the most basic test for determining the corrosion resistance of metals and surface treatment. The solution is sprayed from the mist dispersion tower, a method recommended by ISO for its uniform distribution capability.

An air barrier board is set inside the solution tank, preventing the fluctuation of the solution's pH level.

CASS Test Chambers (Instruments)

CAP-100 / CAP-110 / CAP-120 / CAP-160 / CAP-200

Test standard : ISO 9227, ISO 28340, ASTM B368, JIS Z 2371, JIS H 8502, JIS H 8681-2, JIS D 0201 and more.

Uniform distribution of the salt mist.

International standard ISO 9227 prescribes the salt mist rate 1.5±0.5ml/h at 80cm², while the CAP series enable better accuracy 1.5±0.2ml/h at 80cm².

Air Barrier Board is equipped to suppress PH fluctuations (PAT.).

The Air Barrier Board which is prescribed in the ISO 9227 is equipped in the solution supply tank to block outside air and suppress PH fluctuations.

Short time temperature shifting by the steam heating method (PAT.).

By heating inside the test chamber with a steam pipe, the temperature inside the chamber rises quickly which makes the temperature distribution inside the chamber uniform.

Water Seal Method to seal completely

The lid and the chamber is sealed completely by water.

Slope of the ceiling / lid prevents water drops fall on the test specimen.

The lid and the chamber is sealed completely by water.

Easy-to-clean every corner

The rounded corners in the bottom of the test chamber make it easy to clean.

Transparent parts to check the operating status visually during the tests.

The transparent solution supply tank, air saturator, and the both sides of the top lid allow you to visually check the remaining amount of solution or distilled water and the operating status of the chamber.

Discontinued model : CAP-90V-6, CAP-90V-5, CAP-90V-4, CAP-90V-3, CAP-90V-2

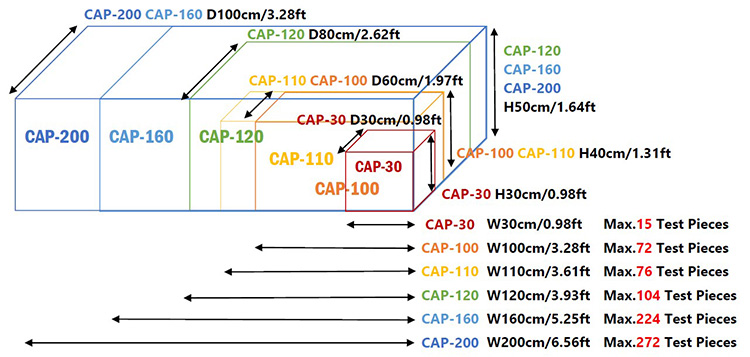

Internal Dimensions Comparison

*Test Piece: 150x70x1mm, per each distance 3mm

| CAP Series Internal Dimensions and Capacity w/o Lid | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model | Width | Depth | Height | Capacity | ||||||

| CAP-30 | 30cm | 0.98ft | 30cm | 0.98ft | 30cm | 0.98ft | 27L | 1.0cu ft | ||

| CAP-100 | 100cm | 3.28ft | 60cm | 1.97ft | 40cm | 1.31ft | 240L | 8.5cu ft | ||

| CAP-110 | 110cm | 3.61ft | 60cm | 1.97ft | 40cm | 1.31ft | 264L | 9.3cu ft | ||

| CAP-120 | 120cm | 3.93ft | 80cm | 2.62ft | 50cm | 1.64ft | 480L | 17.0cu ft | ||

| CAP-160 | 160cm | 5.25ft | 100cm | 3.28ft | 50cm | 1.64ft | 800L | 28.3cu ft | ||

| CAP-200 | 200cm | 6.56ft | 100cm | 3.28ft | 50cm | 1.64ft | 1000L | 35.3cu ft | ||

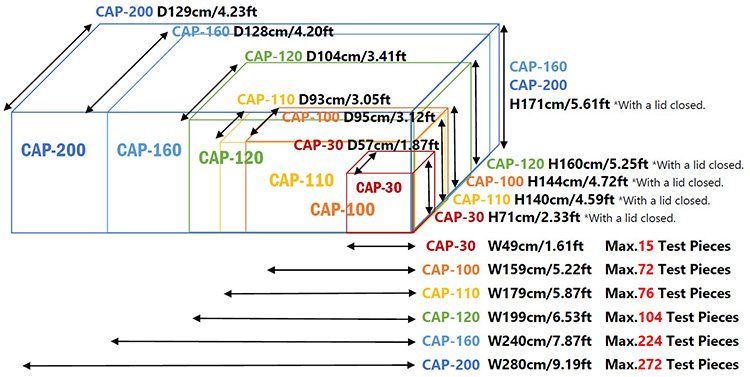

External Dimensions Comparison

*Test Piece: 150x70x1mm, per each distance 3mm

| CAP Series External Dimensions and Weight | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model | Width | Depth | Height | Weight | ||||||

| CAP-30 *Main unit |

49cm | 1.61ft | 57cm | 1.87ft | 71cm | 2.33ft | 50kg | 110lbs | ||

| CAP-100 | 159cm | 5.22ft | 95cm | 3.12ft | 144cm | 4.72ft | 210kg | 463lbs | ||

| CAP-110 | 179cm | 5.87ft | 93cm | 3.05ft | 140cm | 4.59ft | 160kg | 353lbs | ||

| CAP-120 | 199cm | 6.53ft | 104cm | 3.41ft | 160cm | 5.25ft | 360kg | 794lbs | ||

| CAP-160 | 240cm | 7.87ft | 128cm | 4.20ft | 171cm | 5.61ft | 450kg | 992lbs | ||

| CAP-200 | 280cm | 9.19ft | 129cm | 4.23ft | 171cm | 5.61ft | 550kg | 1213lbs | ||

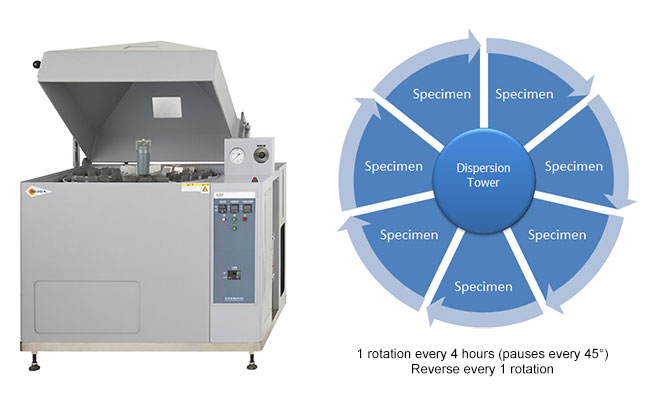

Salt Spray Test Chambers (Instruments) CAP-90VR

Rotation rack allows highest accuracy (PAT.).

A sample rotation mechanism that further pursues the accuracy of test results.

More uniform test results can be obtained than a testing chamber (instrument) in which a sample is fixed and placed in a test chamber. Pauses every 45 ° rotation (1 rotation every 4 hours), and the rotation direction reverses every rotation.

Standard Features

| CASS Test Chambers (Instruments) | |||||||

|---|---|---|---|---|---|---|---|

| Model | CAP-100 | CAP-110 | CAP-120 | CAP-160 | CAP-200 | CAP-90VR | |

| Test item: CASS Test | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| Test temp. range (CASS Test) | 50±1℃ | 50±1℃ | 50±1℃ | 50±1℃ | 50±1℃ | 50±1℃ | |

| Specimen capacity (150x70x1mm each) | 72 pcs | 76 pcs | 104 pcs | 224 pcs | 272 pcs | 72 pcs | |

| Specimen mounting angle (against vertical) | 15°or 20° | 15°or 20° | 15°or 20° | 15°or 20° | 15°or 20° | 15°or 20° | |

| Chamber inner dimensions approx. (WDH) | 100x60x40cm (3.28x1.97x1.31ft) | 110x60x40cm (43.3x23.6x15.7 in) | 120x80x50cm (47.2x31.5x19.7 in) | 160x100x50cm (63.0x39.4x19.7 in) | 200x100x50cm (78.7x39.4x19.7 in) | 99x99x50cm (39.0x39.0x19.7 in) | |

| Capacity w/o lid approx. | 240L (8.5 cu ft) | 264L (9.3 cu ft) | 480L (17.0 cu ft) | 800L (28.3 cu ft) | 1000L (35.3 cu ft) | 490L (17.3 cu ft) | |

| Withstand load of specimen rack | 7 kgf (15.4lbf) | 7.5 kgf (16.5 lbf) | 11 kgf (24.3 lbf) | 20 kgf (44.1 lbf) | 25 kgf (55.1 lbf) | 6 kgf (13.2 lbf) (Roration 1/4rph, Pause, Inversion) | |

| Electric capacity | 3 phase 200V, 10A (ELB: 10A) | 3 phase 200V, 10A (ELB: 10A) | 3 phase 200V, 21A (ELB: 30A) | 3 phase 200V, 22A (ELB: 30A) | 3 phase 200V, 22A (ELB: 30A) | 3 phase 200V, 10A (ELB: 15A) | |

| Tap water requirements approx. | - | - | - | - | - | - | |

| Pure water requirements approx. | TBA | 0.6L/h | 1.3L/h | 1.3L/h | 1.3L/h | 0.6L/h | |

| External dimensions approx.(WDH) | 159x95x144cm (5.22x3.12x4.72ft) | 179x93x140cm (70.5x36.6x55.1 in) | 198x104x160cm (78.0x40.9x63.0 in) | 240x128x171cm (94.5x50.4x67.3 in) | 280x128x171cm (110.2x50.4x67.3 in) | 147x134x166cm (57.9x52.8x65.4 in) | |

| External height with the lid open | 170cm (66.9 in) | 172cm (67.7 in) | 185cm (72.8 in) | 201cm (79.1 in) | 201cm (79.1 in) | 193cm (76.0 in) | |

| Operating weight approx. | 210kgs (463lbs) | 160kgs (353lbs) | 350kgs (772lbs) | 450kgs (992lbs) | 550kgs (1213lbs) | 300kgs (661lbs) | |

*The specifications above are subject to change without notice.

Exhaust Treatment Unit (Optional)

EF-1R / EF-1RW / EF-2R

Completely remove the CASS solution in the exhaust

Exhaust CASS mist during the test is removed by passing it through the water spray. Treated water is circulated and reused by a pump, reducing consumption.

EF-1R for CAP-90V-5, CAP-110, CAP-

EF-1RW for CAP-160, CAP-200

EF-2R for large corrosion test chambers (instruments) CCT series.

Other Options for Corrosion Test Chambers (Instruments)

Exhaust Treatment Unit

Automatic Solution Supplying Unit

Automatic Pure Water Supply System to Air Saturators

Water Recycling Unit

and more.