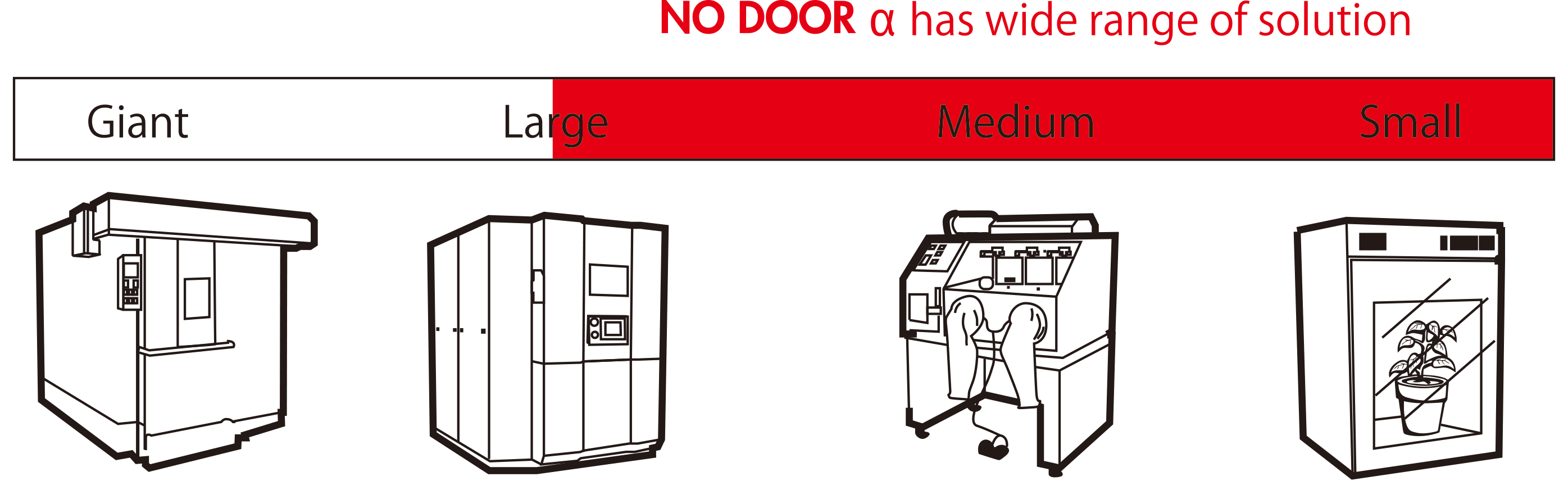

Why we offer new chamber NO DOOR α solve many issues current traditional testing chamber?

There are many testing chambers available in the market. However, the majority of them has a lot of problems. Some of them include uncontrollable temperature, visual problems of the testing area, unstable testing environment among others. All of these will lead to inefficient and unreliable results.

Pros and Cons of Traditional Testing Chambers

Giant size walk-in chamber

Pros - Large testing area, Not expensive compared to giant size walk-in chamber

Cons - Very expensive, Hard to manage temperature, stressful working environment

Large size walk-in chamber

Pros - Large testing area, not expensive compared to giant size walk-in chamber

Cons - Expensive, unstable temperature, stressful working environment

Medium size chamber with two holes

Pros - They can touch the specimen, less stressful working environment

Cons - Hard to operate smoothly, hard to see if screen get foggy, expensive

Small size chamber

Pros - Easy to manage, unexpensive

Cons - Too small, limited testing capabilities, you can not touch the specimen while testing

No Door α Capabilities

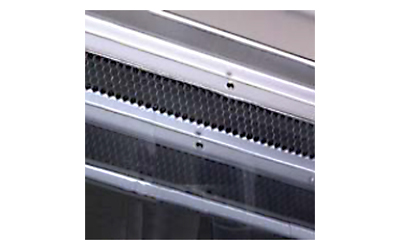

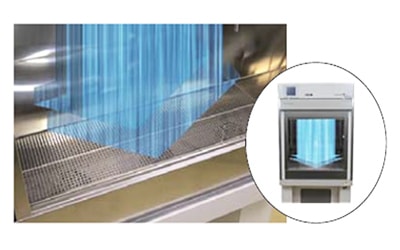

No Door α is the latest innovation in the testing chamber industry. It is boasting a no door chamber that controls humidity and temperature. It features an air curtain that creates straight, soft and stretched air door. You can operate your test specimen without affecting the testing environment. It is equipped with two layers of honeycomb air supply to softly move air in one direction. The gentle air stream prevents contamination from the outside and creates no turbulence even if it's open.

Features

Small observation of test specimen in every angle because it has no door.

Completely open - solving visual problems

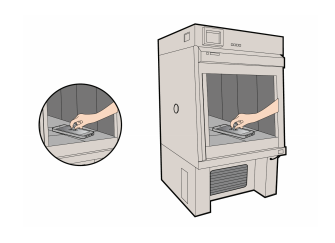

Manipulate specimen freely with precision

Merits

No air stream in the testing chamber

High reliability

Anti Static

Operability

Workability

Uses of No Door α in various industries

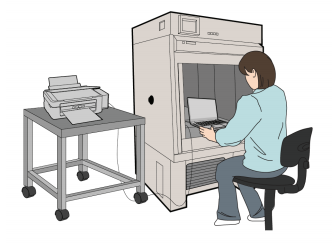

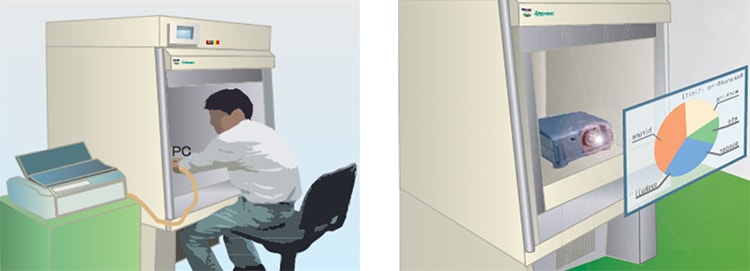

PC with printer

Screen Test, Realiability test

Printer

paper and printing test

Smartphone

Touch screen test, USB testing

Tablet

Reliability of test display

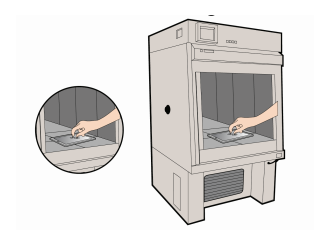

Adhesive tape

Peeling test, adhasive strength test

Features

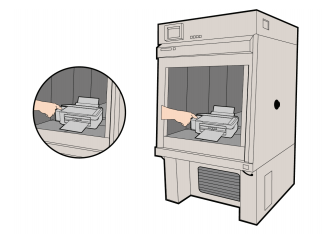

- OPERATIONS AT WILL

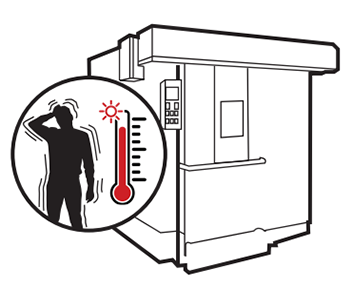

- Operations can be done directly by connecting wires or putting hand inside without feeling the stress of temperature & humidity.

- UPGRADATION OF TESTING EFFICIENCY

- Testing samples can be put in or take out freely without distrubing temperature & humidity inside the chamber which usually occurs during operating & closeing of the door.

- WIDE TEMPERATURE RANGE

- In doorless condition: -20℃~+80℃, 30%RH ~80%RH

Advantages

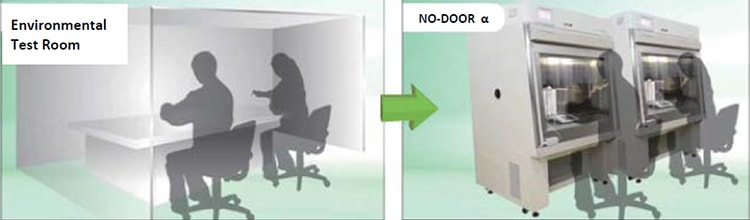

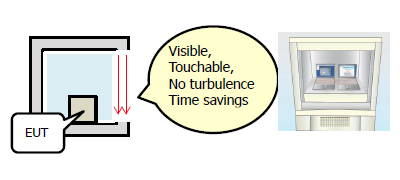

① To manipulate your EUT precisely for operation/image check with Power-on

② To reduce Phisical Stress against Temperature and Humidity

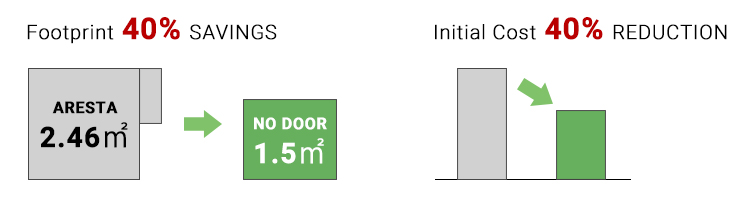

③ To reduce Footprint & Initial Cost

* Compare with Amefrec's Environmental Test Room

Original "Air Curtain" Technology

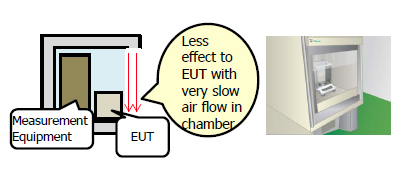

Indirect Temp. Control

Silent & Uniform, Environment in Chamber

SLOW

Preventing, Temp. Contamination, with No Turbulence

STRAIGHT

Double-Laminar, Air Flow

PULL

Air Flow is Stable, during your work

Application

Only EUT in chamber, More efficient Productivity

- Printing performance test of printer

- Continuous tracing test of touch panel

- Electric test at high/low temperature of PCB for automobile, laptop PC and connector

- 100% test of car navigation and HDD on production line

Both EUT & Measurement Equipment in chamber

- 3D high-resolution observation of EUT with microscope

- Water absorbency test of material with electronic balance

- Humidity absorbency test of high functional film with plain inspection equipment

- Hardness evaluation of paint and resin with scratch testing machine

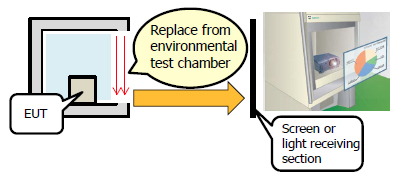

Action from inside to outside

- Projection test of projector

- Camera photographing test

- Laser irradiation test

- Parts test for outside world recognition sensor(Millimeter-wave radar, Stereo camera)

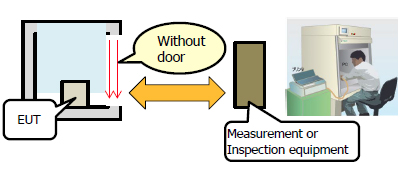

Only EUT in chamber, Measurement Equipment outside

- To improve measurement accuracy of current monitor

- Sports goods evaluation test

- Photographing of destruction test with high speed camera

- Temperature verification of electric part with thermal camera

Specification

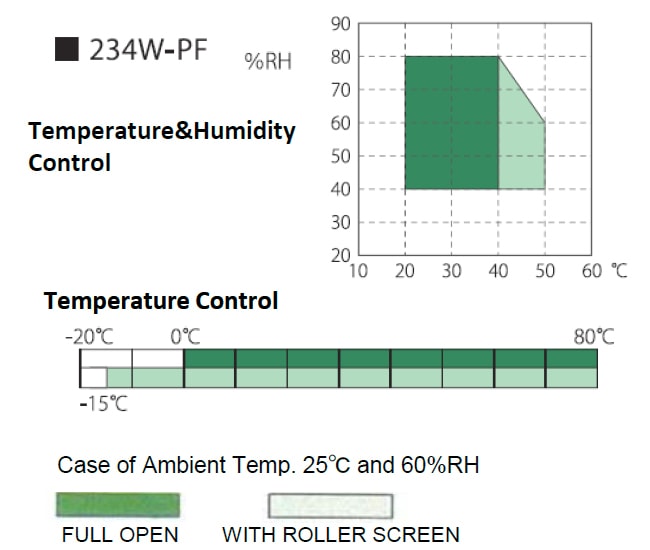

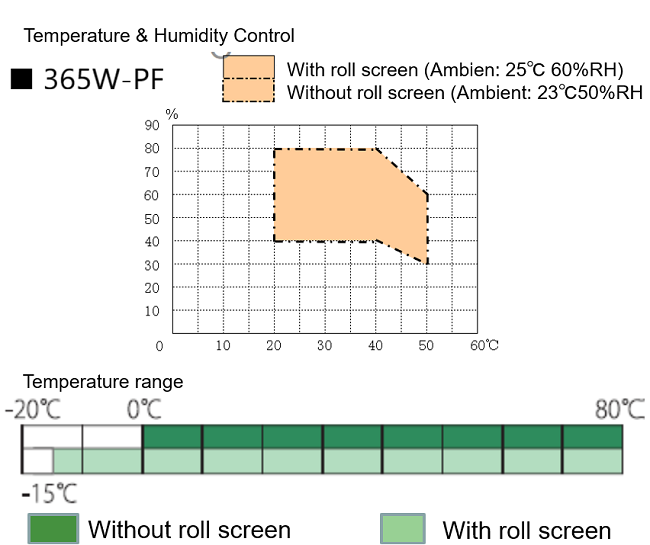

| Model | LST134 | LST234W-PF | LST265 | LST365W-PF |

|---|---|---|---|---|

| Tempreture °C | -15°C ~ +80°C | -20°C ~ +80°C | ||

| Humidity %RH | - | 40%RH ~ 80%RH | - | 30%RH ~ 80%RH |

| Accuracy | ±0.5°C | |||

| RH accuracy | - | ±2% | - | ±2% |

| Temp. distribution | ±1°C between wall and 10cm inside | |||

| Humidity distribution | - | ±5% | - | ±5% |

| Temp. rise time | from +25°C to +80°C in 60 minutes | |||

| Temp. fall time | from +25°C to -15°C in 90 minutes | from +25°C to -20°C in 90 minutes | ||

| Chamber Internal Dimention | "800W x 470D x 590H (mm) (31.5W x 18.5D x 23.2H (inch))" |

"1020W x 670D x 730H (40.1W x 26.4D x 28.7H (inch))" |

||

| External Dimention | "950W x 1050D x 1690H (mm) (37.4W x 41.3D x 66.5H (inch))" |

"1170W x 1290D x 1790H (mm) (46.1W x 50.8D x 70.5H (inch)) " |

||

| Weight | 278Kg (613 lb) | 285Kg (628 lb) | 430Kg (848 lb) | 450Kg (992 lb) |

| Power | 3φ200V 50/60Hz 3.4Kw | 3φ200V 50/60Hz 5.5kW | 3φ200V 50/60Hz 4.0kW | 3φ200V 50/60Hz 6.7kW |

| Defrost System | Hot Gas Bypass system Automatic/Manual | |||

| Safety | "Breaker, Compressor Overload Relay, High Pressure Switch, Thermostat, Fan Circuit Protector, Thermostat for Heater, Water Level Switch etc." |

|||

- Ambient temperature 25°C, Ambient humidity 60%RH, air flow less than or equal to 0.5m/sec with No loads

- When air-cooled refrigerator is used, the waste heat is dissipated into the room.

- Values at 100mm inside chamber from the back, right and left walls

- Recommending distilled water of 1μS/cm supplied at 0.1MPa for humidifier

Option

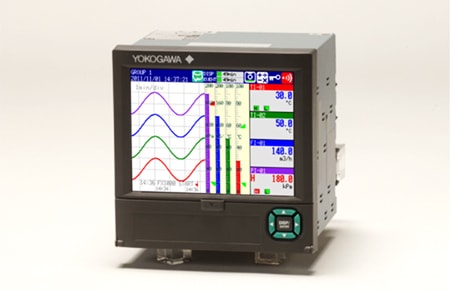

Digital Recorder

Yokogawa FX1006

Pure Water Supply Tank

DI water supply tank

Movie