SHINKEN, a Vibration Test Systems / Shakers' Manufacturer, achieved 2D&3D-Dimensionalization of Electro-Dynamic Vibration Generators, clean solution with the Air-Bearing and Air-Suspension structure and energy saving with the Eco Drive Controller, resulting in obtaining the relevant patents, with an accumulated knowledge of and experience in "Vibration" .

The Features of SHINKEN

Electro-Dynamic Vibration Test Systems

Basically, there are 3 mechanism types of the Vibration Test Systems.

Electro-Dynamic Vibration Test Systems:

Electro-Dynamic Vibration Test Systems:

Most cost-effective systems that SHINKEN uses.

Mechanical Vibration Test Systems:Usable only for simple "far-from-real-world-vibration" sine tests, have almost become extinct as "more-realistic-real-world-vibration" random tests have become more popular.

Hydraulic Vibration Test Systems:Featured by large force, are usually slightly less expensive than the Electro-dynamic Vibration Test Systems as far as larger systems than 50kN with large vibration tables are concerned, while the running cost including the maintenance cost for the Hydraulic Systems is far higher with a lot of oil being used. Also the hydraulic power supply system used for the Hydraulic Systems caused a high noise problem. In addition, the usable upper frequency of the Hydraulic Systems is said to be much lower than that of the Electro-dynamic Systems at about 200Hz as well as to be less controllable due to slow oil response against input control signals.

“Guide Bearing Systems” (Hydrostatic Bearing System / Air Bearing System)

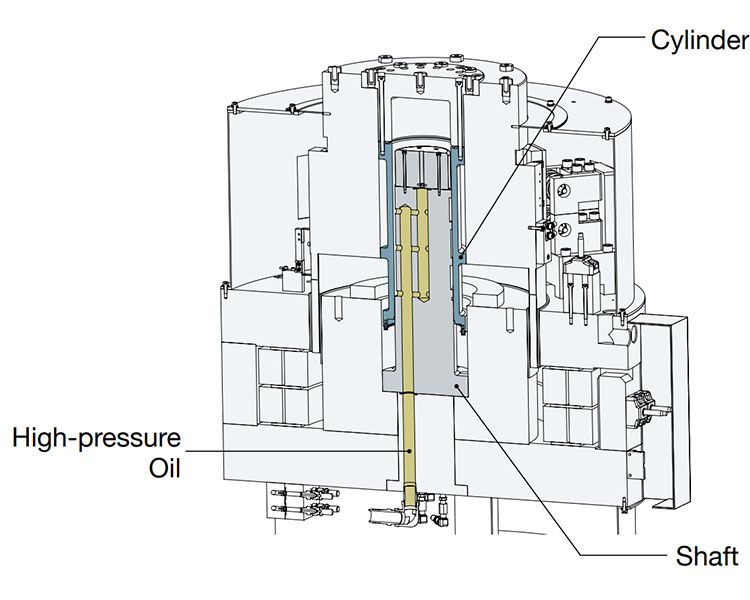

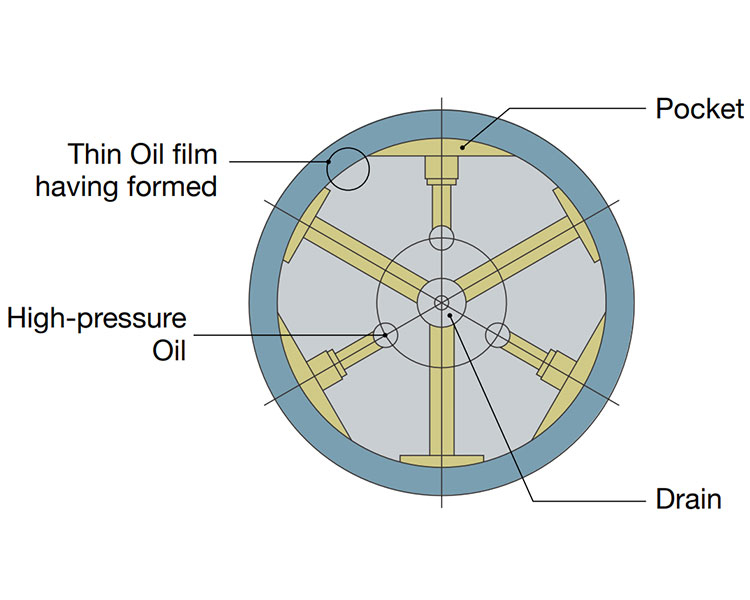

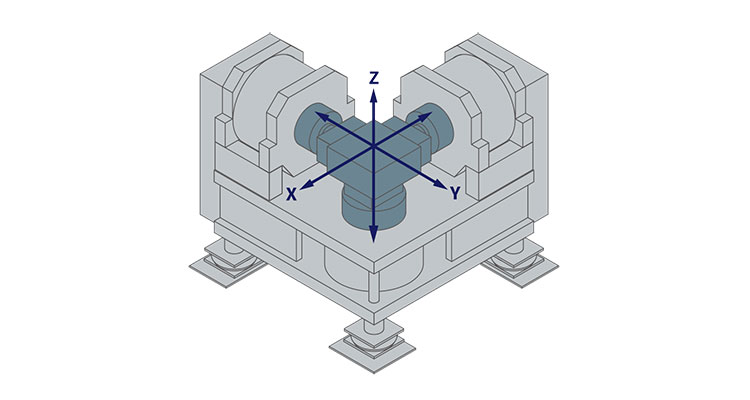

“Guide Bearing Systems” as a Core of Vibration Generators, playing a main role making movements of the Moving Mass of the Vibration Generator smooth. One of the main reasons of high reputation of SHINKEN’s technology is “Guide Bearing Systems”. With SHINKEN only able to employ “Hydrostatic Bearing” and “Air Bearing” for guiding the Moving Mass of the Vibration Generator. Different from the conventional Mechanical Guide Systems, both Guide Bearing Systems involve little mechanical friction thus achieving high waveform fidelity and reduction in consumable parts contributing to cut in maintenance cost.

High waveform fidelity leading to high repeatability of vibration test results

High waveform fidelity of the Hydrostatic Bearing System and Air Bearing System permits for high repeatability of vibration test results thus making it easier to find quality problems.

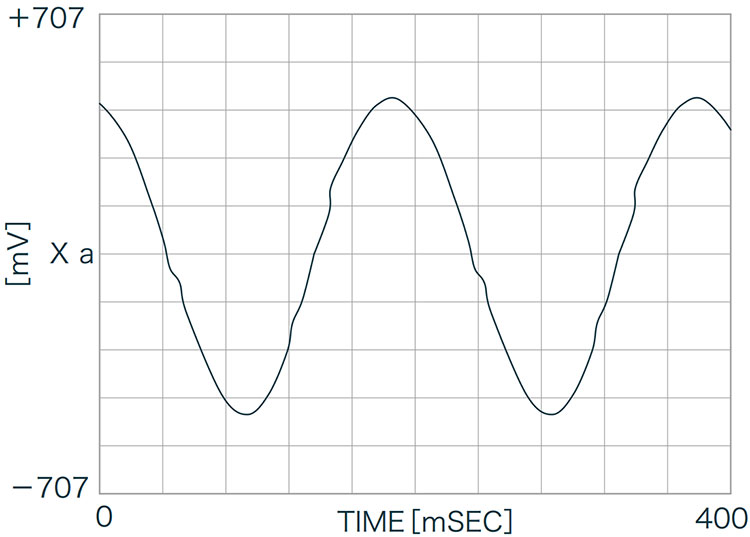

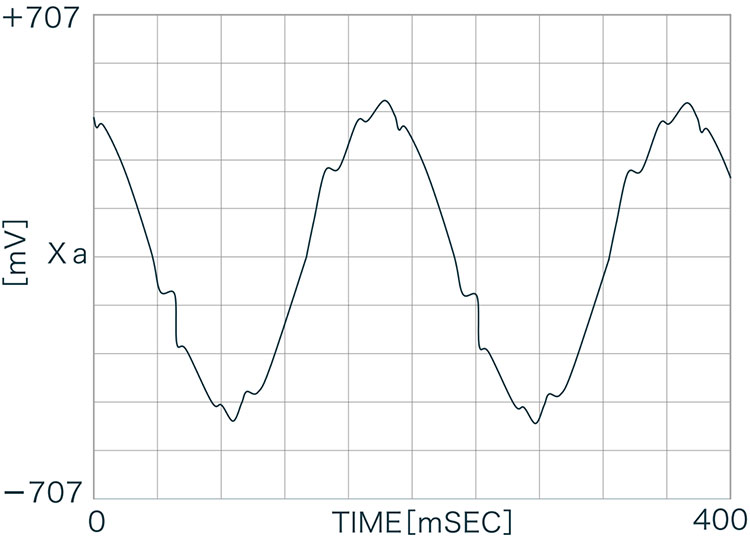

In-company Comparison of Acceleration Waveforms between the Hydrostatic Bearing System and the Conventional Mechanical Bearing System

Hydrostatic Bearing System

Conventional Mechanical Bearing System

Little frictional wear allowing for high waveform fidelity for a long time

Supplying high-pressure oil or high-pressure air to the sliding part can get rid of mechanical friction wear thus keeping high waveform fidelity for a long time.

Internal Structure of Vibration Generator (Typical Example)

Cross Section of Hydrostatic Bearing System

Basics of Vibration Testing

What is the Vibration Test?The Vibration Durability Test is used to ensure that newly designed products can survive in use during their lifespan and operate satisfactorily against any vibration stress, thus inevitably required to win over the tough market.

To learn more about basics of vibration testing as below, please visit "Basics of Vibration Testing" page:

- Purposes of the Vibration Test

- Calculation of Force Output

- 3 Mechanism Types of the Vibration Test Systems

- Principle of the Electro-Dynamic Vibration Generators

- Vibration Test System Configurations

- Test Standard Examples

Multi-Axis Vibration Test Systems / Shakers

SHINKEN succeeded in commercializing the world’s first Electro-Dynamic Multi-Axis Vibration Test System. Since then, SHINKEN has been enjoying the world top-class installation record of Multi-Axis Vibration Test Systems with accumulated knowledge and long years experience as well as its uniquely-designed Hydrostatic Bearing System which minimizes cross-talks among axes and also makes the Multi-Axis Vibration Generators compact. In addition to simultaneous excitation, Multi-Axis Vibration Test Systems have been used for the sequential test of each axis thus contributing to time saving and labor elimination as no troublesome vertical & horizontal tables handling and also no specimen unloading & loading are needed. 2-axis and 3-axis Vibration Test Systems are available.

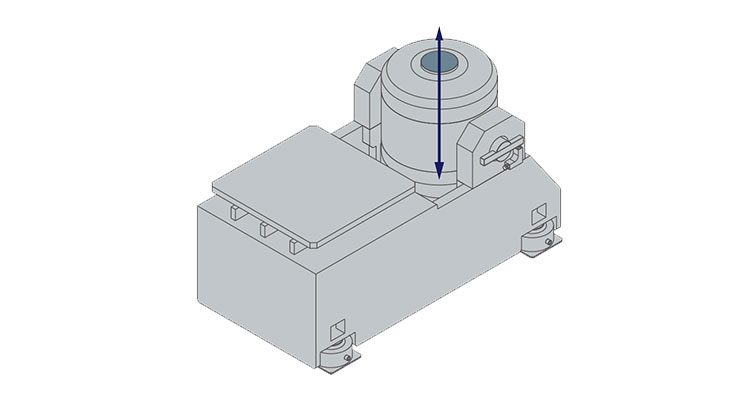

Single-Axis Vibration Test Systems / Shakers

The Single-Axis Vibration Test Systems, the most common, have been widely used for many years. Even for Conventional Single-Axis Vibration Test Systems, SHINKEN has been meeting various customer's requirements with unique technologies such as Air Bearing and Hydrostatic Bearing for guiding the Movable Mass and Bellows-free Air Suspension for Axial Support using Back Pressure from the Air Bearing System; N Type: Air Bearing & Air Suspension (Patented) featured by High Fidelity, Low Cross-Talks, Cleanness and Fewer Consumable Parts L Type: Hydrostatic Bearing featured by High Eccentric Moment, Low Cross-talks and High Durability.

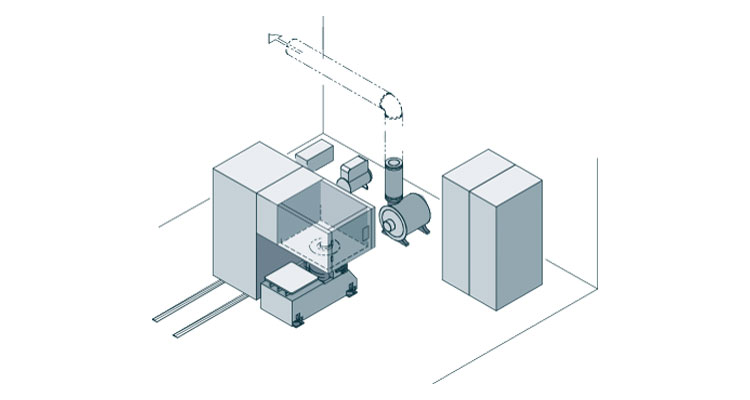

Vibration Combined Environmental Test Systems / Shakers

Combined Environmental Test Systems are for combination tests of Vibration, Temperature and Humidity with Vibration Test Systems and Environmental Chamber thus realizing more realistic environment during products in use or transportation and enhancing the quality of the products. Combined Environmental Test Systems with not only Vertical Single-Axis Vibration Test Systems but also Single-Axis Vibration Test Systems with Horizontal Tables and Multi-Axis Vibration Test Systems are available.

Digital Vibration Controllers

D-59 Series Digital Vibration Controllers for Windows 10, which can be used for not only Electro-dynamic Shakers but also Hydraulic Shakers, are featured by user-friendly usability thus enabling complicated vibration tests to be carried out easily as well as a variety of control functions available such as Sine, PSD Random, Shock, Mixed Mode, RSTD, Waveform Reproduction etc. and also input channels being expandable up to 8.

Model Selection by Applications

Made-to-order systems are available. Please feel free to contact us.

| System For | Details on Application |

Multi-Axis | Single-Axis | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| G-6 | G-8 | G-0 | G-9 | G-5 | G-4 | G-3 | G-2 | |||

Aseismic |

Seismic Simulation for Land Liquefaction |

|||||||||

| Anti-seismic Simulation for Structure Models |

||||||||||

| Seismic Simulation for Furniture Fall Prevention |

||||||||||

| Anti-seismic Simulation for Industrial Equipment |

||||||||||

| Calibration for Seismic-related Sensors |

||||||||||

| Transportation Packaged Goods  |

Packaged Goods | |||||||||

| Packing Materials & Containers |

||||||||||

| Transportation Actual Travelling Simulation |

||||||||||

| Shock Simulation during Transportation |

||||||||||

| Electronic & Electronic Apparatus  |

Small Electric & Electronic Parts and PC Boards |

|||||||||

| Home Appliances ( White Goods) |

||||||||||

| Sensors | ||||||||||

| Personal Computer and Computer Terminals |

||||||||||

| Mobile Phones, Cameras and Tablet-type Devices |

||||||||||

| Rechargeable Lithium Ion Batteries |

||||||||||

| Precision Equipment | ||||||||||

| Large Electric Apparatus such as Generators |

||||||||||

Automotive |

Bodies, Chassis | |||||||||

| Tires, Suspensions | ||||||||||

| Seats | ||||||||||

| Radiators | ||||||||||

| Engines, Intake & Exhaust Systems |

||||||||||

| Battery Modules & Packs |

||||||||||

| Engine Control Units, Electrical Equipment |

||||||||||

| Instruments | ||||||||||

| Audio Systems, Car Navigation Systems |

||||||||||

| Sensors | ||||||||||

| Trouble Solutions | ||||||||||

Railway & Ship |

Instruments, Electrical Equipment |

|||||||||

| Motors, Invertors | ||||||||||

| Compressors | ||||||||||

Aerospace |

Sensors, Communications Systems |

|||||||||

| Instruments, Electrical Equipment |

||||||||||

| Engine Parts, Propulsion Systems |

||||||||||

Other |

Calibration for Sensors and Instruments |

|||||||||

| Educational Purposes, Model Tests |

||||||||||

| Power Filling, Fluid facilitation |

||||||||||

Model Descriptions

Made-to-order systems are available. Please feel free to contact us.

Made-to-order systems are available. Please feel free to contact us.

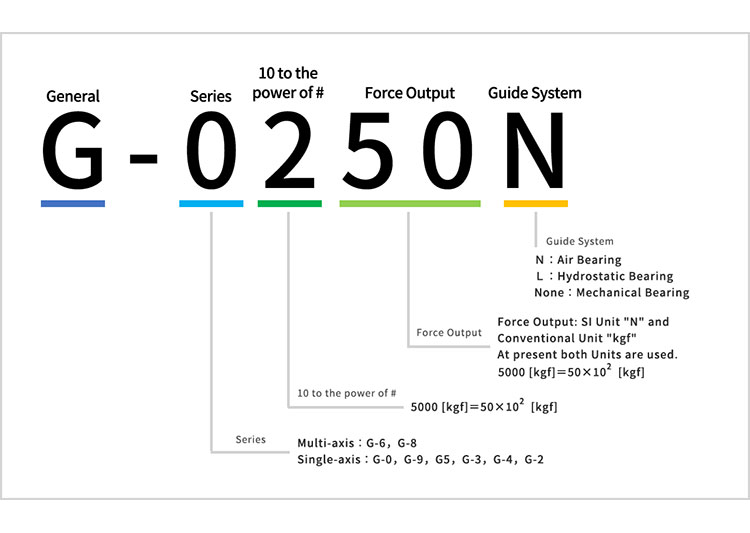

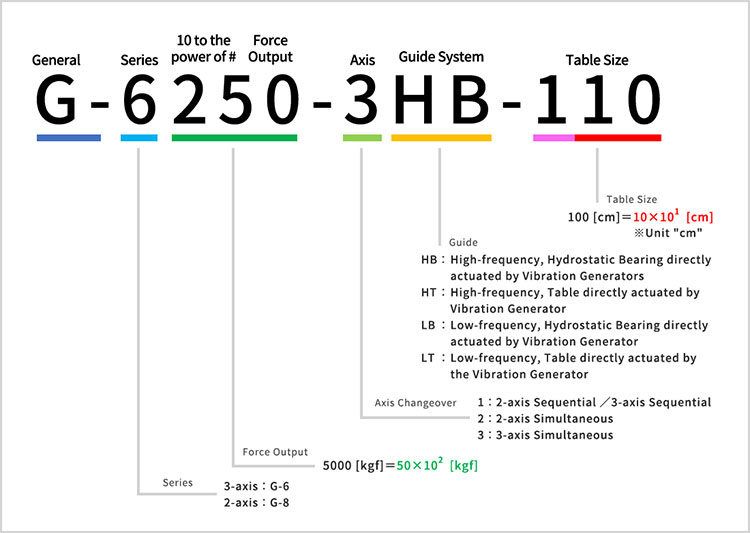

General Model Description