Vibration Combined Environmental Test Systems / Shakers

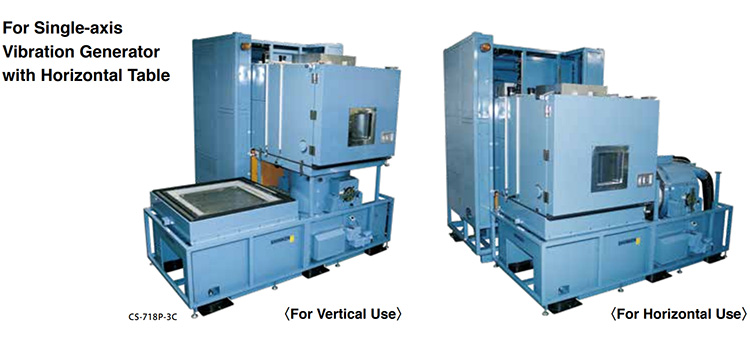

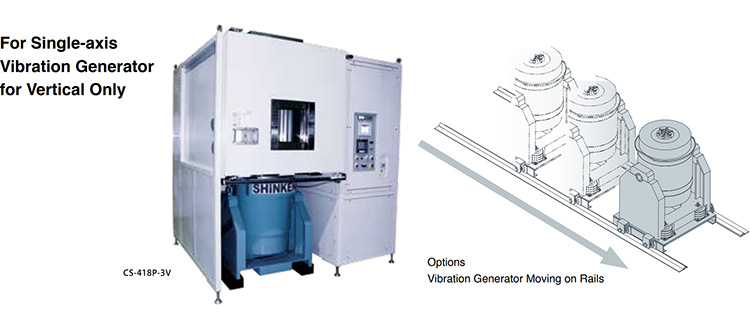

Combined Environmental Test Systems are for combination tests of Vibration, Temperature and Humidity with Vibration Test Systems and Environmental Chamber thus realizing more realistic environment during products in use or transportation and enhancing the quality of the products. Combined Environmental Test Systems with not only Vertical Single-Axis Vibration Test Systems but also Single-Axis Vibration Test Systems with Horizontal Tables and Multi-Axis Vibration Test Systems are available.

Combined Environmental Test Systems CS Series

Combined Environmental Test Systems with Vibration Test Systems and Environmental Chambers

| System Model | CS-418P-1C | CS-418P-2C | CS-418P-3C | CS-418P-4C |

|---|---|---|---|---|

| Internal Dimensions | 600×600×600mm (1.97x1.97x1.97ft) | 800×800×800mm (2.62x2.62x2.62ft) | 1000×1000×1000mm (3.28x3.28x3.28ft) | 1200×1200×1200mm (3.93x3.93x3.93ft) |

| Temperature Range | -40℃~+180℃ (-40~356℉) | |||

| Humidity Range | 20%~98%R.H (with Temperature Conditions) | |||

| Temperature & Humidity Fluctuation | Within ±0.5℃ / ±4.0%RH (excluding Heat-up & Cool-down Time) | |||

| Temperature Distribution | Within ±3.0℃ | |||

| Temperature Ramp Time | 20℃→-180℃:Within 90 min / 20℃→-40℃:Within 60 min ※with Total Mass of about 40 kg (Specimen & Fixture) | |||

| Body Material | Exterior : Bonderized Steel / Interior : SUS304 2B | |||

| Heat Insulation Material | Glass Wool etc. | |||

| Temp. & Humidity Controller | TFT Display, Touch Panel Operation | |||

| Fittings Accessories | Lid Cover for Independent Use, Cable Port 50φ×1, Hour Meter×1, Waterdrop-proof Sheet, Height Adjustors | |||

| Chamber-VTS linkage | Start and Stop with Time Signals from Controller, Linked Interlocks | |||

| Moving Method | Chamber Moving on Rails | |||

| Docking with Shaker | Piggy-back Docking | |||

| Protective Devices | Breaker, Fridge Overload Relay, Over Heat Prevention, External Alarm Terminal Fridge High-pressure Switch, Boil Dry Protector, Door Switches, Emergency Stop Switch, Water Lack, etc. | |||

Docking Methods with Vibration Generators

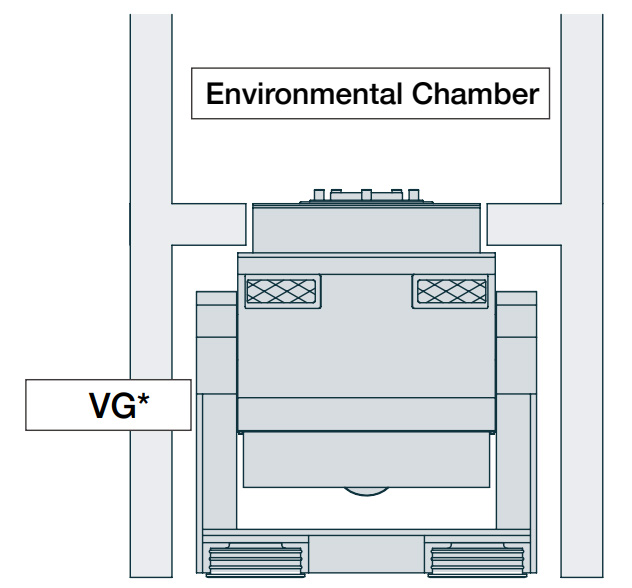

Piggy-Back Docking

With the upper part of the Vibration Generator modified with stainless steel for heat isolation, no additional Coupling Jig is needed thus keeping the max. acceleration and upper frequency as the Vibration Test System is used independently.

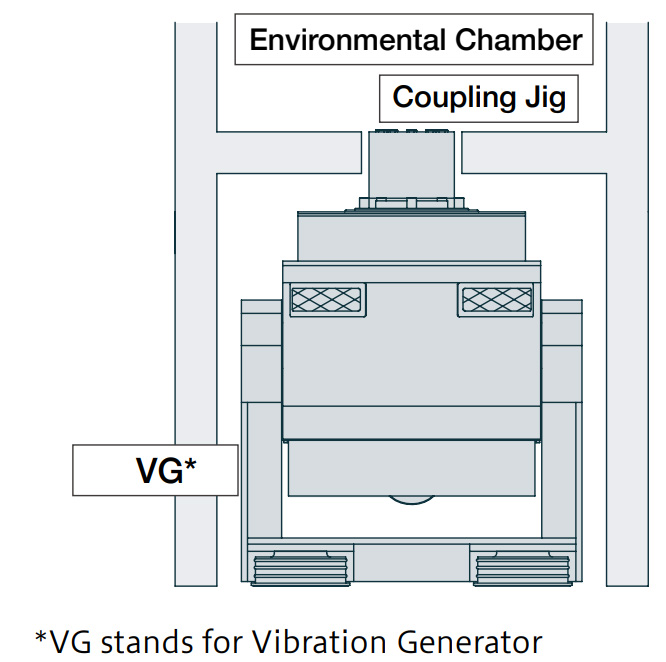

Coupling Jig Docking

The Coupling Jig is generally used for docking the Vibration Generator and the Chamber but the max. acceleration becomes smaller and upper frequency becomes lower.