SSXC Series - Stainless Steel Ball Bearings with Setscrew

SMT SSXC Series are Stainless steel ball bearings with setscrews. Applicaiton is food processing machinery, cleaning equipment, LCD and semiconductor manufacturing equipment, carrier device in watery environment, other equipment used in high temperature and humidity environment.

Features

- Excellent corrosion resistance

- Improvement of workabitity to mount Fastening by setscrew allows loose fit between shaft and bore

- Secure fastening by setscrew prevents creeping between shaft and bore

- Free from abrasion powder caused by creeping Suitable for use in such environment like clean room where powder dust is not allowed

- No need for collars to fix or locate bearings

Applications

Food processing machinery, cleaning equipment, LCD and semiconductor manufacturing equipment, carrier device in watery environment, other equipment used in high temperature and humidity environment

Specification

Standard Specifications

| Outer and Inner Rings | AISI 440C |

| Ball *1 | AISI 440C |

| Retainer | AISI 304 |

| Shield | AISI 304 |

| Setscrew | AISI 304 equivalent |

| Lubricant *2 | Heat-resistant grease |

Special specifications also available

*1 Ceramic balls(Silicon Nitride Si3N4)

*2 Heat- and chemical-resistant fluorine grease, food grade grease, and other special grease

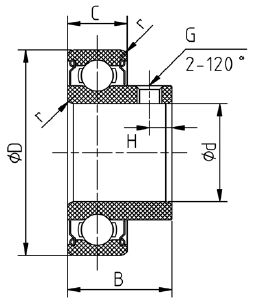

Dimensions

| Bearing Numbers | d | D | B | C | G | H | r min | Cr | C0r | |

| mm | Tolerance | mm | mm | mm | mm | mm | mm | N | N | |

| SS XC900 ZZ | 10 | +0.015 0 | 22 | 13 | 6 | M3 | 3. 0 | 0.3 | 2700 | 1270 |

| SS XC000 ZZ | 10 | 26 | 15 | 8 | M3 | 3. 0 | 0.3 | 4600 | 1970 | |

| SS XC200 ZZ | 10 | 30 | 17 | 9 | M4 | 3. 5 | 0.6 | 5100 | 2390 | |

| SS XC901 ZZ | 12 | 24 | 13 | 6 | M3 | 3. 0 | 0.3 | 2890 | 1460 | |

| SS XC001 ZZ | 12 | 28 | 15 | 8 | M3 | 3. 0 | 0.3 | 5100 | 2390 | |

| SS XC201 ZZ | 12 | 32 | 19 | 10 | M4 | 3. 5 | 0.6 | 6800 | 3050 | |

| SS XC902 ZZ | 15 | 28 | 14 | 7 | M3 | 3. 0 | 0.3 | 4300 | 2250 | |

| SS XC002 ZZ | 15 | 32 | 16.5 | 9 | M3 | 3. 0 | 0.3 | 5600 | 2840 | |

| SS XC202 ZZ | 15 | 35 | 20 | 11 | M4 | 3. 5 | 0.6 | 7650 | 3750 | |

| SS XC903 ZZ | 17 | 30 | 14 | 7 | M3 | 3. 0 | 0.3 | 4600 | 2550 | |

| SS XC003 ZZ | 17 | 35 | 17.5 | 10 | M4 | 3. 5 | 0.3 | 6000 | 3250 | |

| SS XC203 ZZ | 17 | 40 | 21 | 12 | M5 | 4. 5 | 0.6 | 9600 | 4800 | |

| SS XC904 ZZ | 20 | +0.018 0 | 37 | 18 | 9 | M4 | 3. 5 | 0.3 | 6400 | 3700 |

| SS XC004 ZZ | 20 | 42 | 21 | 12 | M5 | 4. 5 | 0.6 | 9400 | 5050 | |

| SS XC204 ZZ | 20 | 47 | 23 | 14 | M5 | 4. 5 | 1.0 | 12800 | 6650 | |

| SS XC905 ZZ | 25 | 42 | 18 | 9 | M4 | 3. 5 | 0.3 | 7000 | 4550 | |

| SS XC005 ZZ | 25 | 47 | 22 | 12 | M5 | 4. 5 | 0.6 | 10100 | 5850 | |

| SS XC205 ZZ | 25 | 52 | 26 | 15 | M5 | 4. 5 | 1.0 | 14000 | 7900 | |

| SS XC906 ZZ | 30 | 47 | 18 | 9 | M4 | 3. 5 | 0.3 | 7250 | 5000 | |

| SS XC006 ZZ | 30 | 55 | 24.5 | 13 | M5 | 5. 0 | 1.0 | 13200 | 8300 | |

| SS XC206 ZZ | 30 | 62 | 28.5 | 16 | M6 | 5. 5 | 1.0 | 19500 | 11300 | |

| SS XC207 ZZ | 35 | +0.021 0 | 72 | 33 | 17 | M6 | 6 . 5 | 1.1 | 25700 | 15400 |

Precautions

Please refer to the chart for the tightening torque. Too much torque may damage the bearing. Adhesive bond is not recommended that may increase the tightening force and result in the breakage of bearing.

*The performance data and expressions are provided as a general guide only.

The specifications are subject to change without notice for the improvement of performance.

Recommended tightening torque

| Setscrew size | Tightening torque N・m |

| M3 | 0.7 |

| M4 | 1.8 |

| M5 | 3.0 |

| M6 | 4.0 |