SH series - Stainless Ball Bearing with Aligning Ring

Addition of aligning function to standard stainless ball bearings can allow them to require less maintenance by allowing the flexure of large roller, together with corrosion resistance of stainless steel.

Features

Corrosion Resistance

Made of AISI440C stainless steel, and suitable in corrosive environment, in clean room and for food machinery.

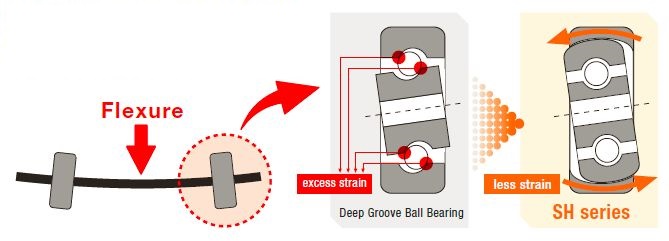

Aligning Function

Reducing the excess strain on bearing, by aligning the flexure of the conveyor roller’s shaft or the error of shaft center.

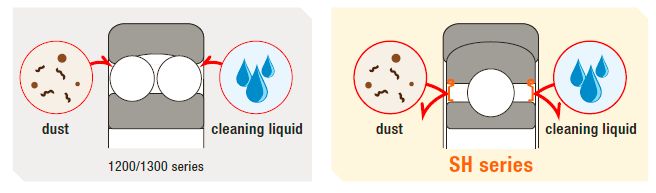

Dust Resistance

Available with seals and shields, and suitable in dusty or watery environment.

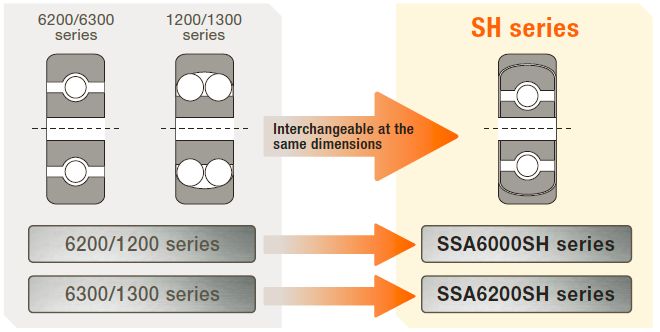

Interchangeability

Interchangeable to 6200, 6300, 1200 and 1300 series bearings. The dimensions are the same, except the width of the bearing inside.

Other

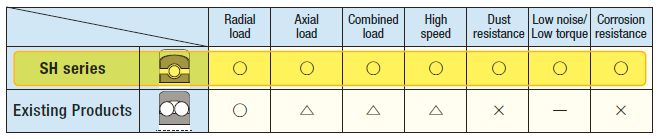

The SH series bearings have more advantages than the standard self-aligning bearings made of SAE52100 steel.

Applications

Roller for chemical film conveyor, clean room application, food machinery, glass substrate conveyor, cleaning system, papermaking machine, printing machine, etc.

Specials

The SH series bearings are available with special lubricants like H1grade food grease, low-emission grease, fluorine grease or solid lubricant for vacuum condition, and ceramic balls and fluororesin seals can be used upon request.

The SH series bearings are available with special lubricants like H1grade food grease, low-emission grease, fluorine grease or solid lubricant for vacuum condition, and ceramic balls and fluororesin seals can be used upon request.

The SH series bearings are also available in the combination with our standard stainless bearings:

6S series made of AISI304 stainless steel,

4S series made of AISI630 stainless steel, and

SS XC series with set screws.

Specification

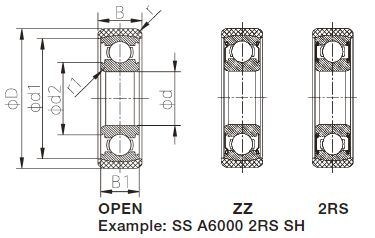

Type SSA

| Aligning ring | AISI440C |

| Outer/Inner rings | AISI440C |

| Balls | AISI440C |

| Retainer | AISI304 |

| Shields | AISI304 |

| Seals | NBR |

| Lubricant* | Heat resistant grease |

*Available with ceramic balls(Si3N4)

*Available with fluorin rubber seal

*Available with fluorine grease of chemical and heat resistance, food grade grease and other special greases.

| Bearing Numbers | d | D | B | B1 | d1 | d2 | r min. | r1 min. | Cr | COr | Interchangeble |

| mm | mm | mm | mm | mm | mm | mm | mm | N | N | ||

| SS A6000 SH | 10 | 30 | 9 | 8 | 24.70 | 13.31 | 0.6 | 0.3 | 4600 | 1970 | 6200, 1200 |

| SS A6200 SH | 10 | 35 | 11 | 9 | 28.25 | 16.01 | 0.6 | 0.6 | 5100 | 2390 | 6300, 1300 |

| SS A6001 SH | 12 | 32 | 10 | 8 | 26.48 | 16.01 | 0.6 | 0.3 | 5100 | 2390 | 6201, 1201 |

| SS A6201 SH | 12 | 37 | 12 | 10 | 30.14 | 16.75 | 1.0 | 0.6 | 6800 | 3050 | 6301, 1301 |

| SS A6002 SH | 15 | 35 | 11 | 9 | 30.37 | 19.01 | 0.6 | 0.3 | 5600 | 2840 | 6202, 1202 |

| SS A6202 SH | 15 | 42 | 13 | 11 | 32.85 | 20.25 | 1.0 | 0.6 | 7650 | 3750 | 6302, 1302 |

| SS A6003 SH | 17 | 40 | 12 | 10 | 33.21 | 21.51 | 0.6 | 0.3 | 6000 | 3250 | 6203, 1203 |

| SS A6203 SH | 17 | 47 | 14 | 12 | 37.91 | 22.25 | 1.0 | 0.6 | 9600 | 4800 | 6303, 1303 |

| SS A6904 SH | 20 | 42 | 12 | 9 | 35.30 | 24.00 | 0.6 | 0.3 | 6400 | 3700 | 6004 |

| SS A6004 SH | 20 | 47 | 14 | 12 | 40.01 | 25.11 | 1.0 | 0.6 | 9400 | 5050 | 6204, 1204 |

| SS A6204 SH | 20 | 52 | 15 | 14 | 44.94 | 26.99 | 1.1 | 1.0 | 12800 | 6650 | 6304, 1304 |

| SS A6005 SH | 25 | 52 | 15 | 12 | 44.94 | 30.12 | 1.0 | 0.6 | 10100 | 5850 | 6205, 1205 |

| SS A6205 SH | 25 | 62 | 17 | 15 | 49.67 | 32.84 | 1.1 | 1.0 | 14000 | 7900 | 6305, 1305 |

| SS A6006 SH | 30 | 62 | 16 | 13 | 52.99 | 35.91 | 1.0 | 1.0 | 13200 | 8300 | 6206, 1206 |

| SS A6206 SH | 30 | 72 | 19 | 16 | 59.52 | 38.54 | 1.1 | 1.0 | 19500 | 11300 | 6306, 1306 |

| SS A6007 SH | 35 | 72 | 17 | 14 | 59.9 | 41.95 | 1.1 | 1.0 | 16000 | 10300 | 6207, 1207 |

| SS A6008 SH | 40 | 80 | 18 | 15 | 66.43 | 47.20 | 1.1 | 1.0 | 16800 | 11600 | 6208, 1208 |

| SS A6210 SH | 50 | 110 | 27 | 20 | 86.62 | 59.87 | 2.0 | 1.1 | 35100 | 23200 | 6310, 1310 |

※The performance values on this catalog are not guaranteed and the specifications may change without prior notice for improved performance.

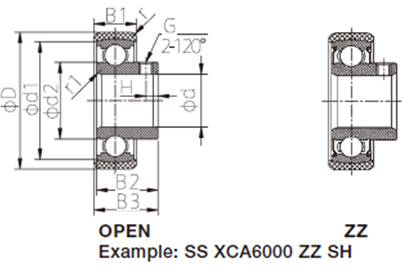

Type SSXCA with Set screw

| Aligning ring | AISI440C |

| Outer/Inner rings | AISI440C |

| Balls | AISI440C |

| Retainer | AISI304 |

| Shieldsu | AISI304 |

| Set screw | SUS304 equivalent |

| Lubricant* | Heat resistant grease |

*Available with ceramic balls(Si3N4)

*Available with fluorine grease of chemical and heat resistance, food grade grease and other special greases.

| Bearing Numbers | d | D | B1 | B2 | B3 | G | H | d1 | d2 | r min. | r1 min. | Cr | COr | |

| mm | tolerance | mm | mm | mm | mm | - | mm | mm | mm | mm | mm | N | N | |

| SS XCA6000 SH | 10 | +0.015 0 | 30 | 9 | 15 | 15.5 | M3 | 3.0 | 24.70 | 14.86 | 0.6 | 0.3 | 4600 | 1970 |

| SS XCA6200 SH | 10 | 35 | 11 | 17 | 18 | M4 | 3.5 | 28.25 | 17.45 | 0.6 | 0.6 | 5100 | 2390 | |

| SS XCA6001 SH | 12 | 32 | 10 | 15 | 16 | M3 | 3.0 | 26.48 | 17.45 | 0.6 | 0.3 | 5100 | 2390 | |

| SS XCA6201 SH | 12 | 37 | 12 | 19 | 20 | M4 | 3.5 | 30.14 | 18.19 | 1.0 | 0.6 | 6800 | 3050 | |

| SS XCA6002 SH | 15 | 35 | 11 | 16.5 | 17.5 | M3 | 3.0 | 30.37 | 20.45 | 0.6 | 0.3 | 5600 | 2840 | |

| SS XCA6202 SH | 15 | 42 | 13 | 20 | 21 | M4 | 3.5 | 32.85 | 21.69 | 1.0 | 0.6 | 7650 | 3750 | |

| SS XCA6003 SH | 17 | 40 | 12 | 17.5 | 18.5 | M4 | 3.5 | 33.21 | 22.95 | 0.6 | 0.3 | 6000 | 3250 | |

| SS XCA6203 SH | 17 | 47 | 14 | 21 | 22 | M5 | 4.5 | 37.91 | 24.68 | 1.0 | 0.6 | 9600 | 4800 | |

| SS XCA6904 SH | 20 | +0.018 0 | 42 | 12 | 18 | 19.5 | M4 | 3.5 | 35.30 | 25.45 | 0.6 | 0.3 | 6400 | 3700 |

| SS XCA6004 SH | 20 | 47 | 14 | 21 | 22 | M5 | 4.5 | 40.01 | 27.44 | 1.0 | 0.6 | 9400 | 5050 | |

| SS XCA6204 SH | 20 | 52 | 15 | 23 | 23.5 | M5 | 4.5 | 44.94 | 29.22 | 1.1 | 1.0 | 12800 | 6650 | |

| SS XCA6005 SH | 25 | 52 | 15 | 22 | 23.5 | M5 | 4.5 | 44.94 | 32.04 | 1.1 | 0.6 | 10100 | 5850 | |

| SS XCA6205 SH | 25 | 62 | 17 | 26 | 27 | M5 | 4.5 | 49.67 | 33.92 | 1.1 | 1.0 | 14000 | 7900 | |

| SS XCA6006 SH | 30 | 62 | 16 | 24.5 | 26 | M5 | 5.0 | 52.99 | 37.93 | 1.0 | 1.0 | 13200 | 8300 | |

| SS XCA6206 SH | 30 | 72 | 19 | 28.5 | 30 | M6 | 5.5 | 59.52 | 40.60 | 1.1 | 1.0 | 19500 | 11300 | |

※The performance values on this catalog are not guaranteed and the specifications may change without prior notice for improved performance.

Fits

Recommended fit to housing bore is H class of tolerance range.

Please consult with us, in case of special use conditions.